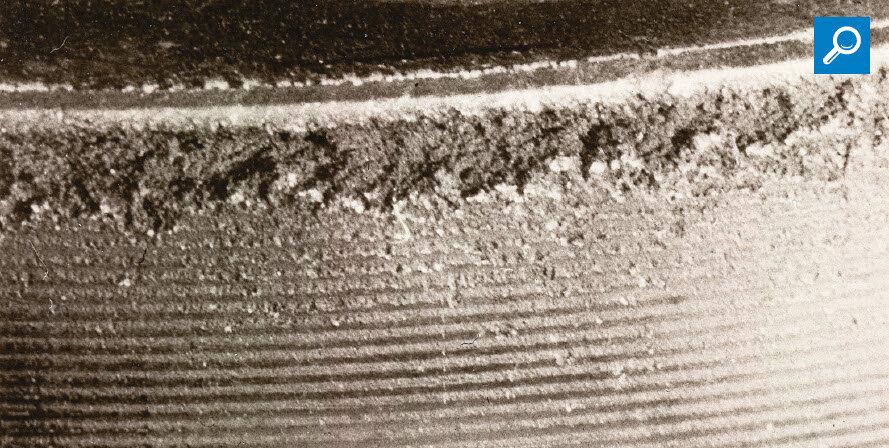

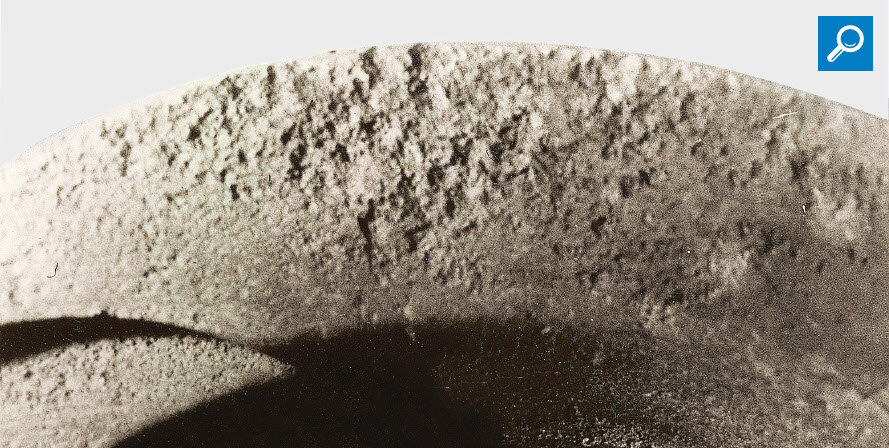

Erosion on the piston top land and on the piston crown (petrol engines)

DESCRIPTION OF THE DAMAGE

Erosion-type removal of material from the piston top land (Fig. 2) or surface of the piston crown (Fig. 3).

DAMAGE ASSESSMENT

Erosion-type removal of material from the piston top land and from the piston crown always occurs as a result of extended periods of knocking combustion (medium severity). In the process, pressure waves spread in the cylinder and run down between the piston top land and the cylinder wall as far as the first compression ring. At the reversal point of the pressure wave, the kinetic energy tears out tiny particles from the surface of the piston.

POSSIBLE CAUSES FOR THE DAMAGE

- Fuel without suitable anti-knock properties. The fuel quality must correspond to the compression ratio of the engine, i.e. the octane rating of the fuel must cover the octane requirements of the engine under all operating conditions.

- Petrol has been contaminated with diesel. Cause: accidental refuelling with the wrong type of fuel or shared use of tanks or canisters for both types of fuel. Even very small amounts of diesel are already enough to significantly lower the octane rating of the petrol.

- Large quantities of oil in the combustion chamber, caused for example by worn piston rings, valve guides or the exhaust gas turbocharger, will reduce the anti-knock properties of the fuel.

- Excessively high compression ratio. Cause: combustion residue on the piston crowns and cylinder head or excessive machining of the block surface and cylinder head surface for engine reconditioning or tuning purposes.

- Ignition timing too advanced.

- Mixture too lean, resulting in higher combustion temperatures.

- Intake air temperatures too high. Causes: inadequate ventilation of the engine compartment or exhaust gas back pressure, failure to switch the intake air flap to summer operation in a timely manner or a faulty automatic switchover mechanism (particularly on older carburettor engines).

- Failure of the knock control system.

- Modifications to the control unit software.

NOTE

Modern engines are equipped with systems designed to detect knocking combustion. This knock control system counteracts knocking combustion by adapting the ignition timing. However, the knock control system cannot intervene until knocking combustion has already occurred. Even if the knock control system is fully functional, the risk of damage cannot be ruled out if:

- the control range of the engine control unit is no longer sufficient, or

- the knock limit is constantly reached.

Side info