Piston damage due to abnormal combustion

Abnormal combustion in petrol engines

The combustion of the air-fuel mixture in the cylinder follows a precisely defined process. It is started by the spark from the spark plug shortly before top dead centre (TDC). The flame spreads from the spark plug with a circular flame front and crosses the combustion chamber at a steadily increasing combustion speed of 5–30 m/s. The pressure in the combustion chamber rises steeply as a result and reaches its maximum value shortly after TDC. However, this normal combustion process can be disturbed by various factors, which can essentially be reduced to three different cases of combustion faults:

1. Glow ignition (pre-ignition):

Causes thermal overstressing of the piston.

2. Knocking combustion:

Causes erosion of material and mechanical overload on the piston and the crankshaft drive.

3. Fuel flooding:

Causes wear in conjunction with oil consumption as well as piston seizures.

1. Glow ignition (pre-ignition):

Causes thermal overstressing of the piston.

2. Knocking combustion:

Causes erosion of material and mechanical overload on the piston and the crankshaft drive.

3. Fuel flooding:

Causes wear in conjunction with oil consumption as well as piston seizures.

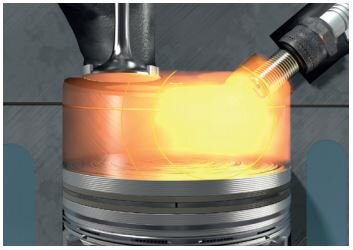

Normal combustion

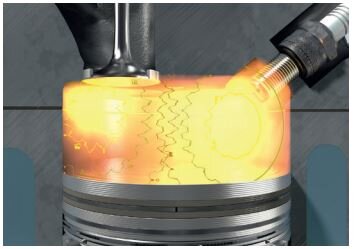

Knocking combustion

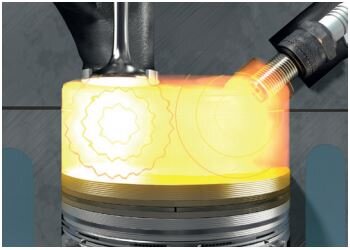

Glow ignition

Additional information for 1. Glow ignition (pre-ignition):

In the case of glow ignition, a part that is glowing in the combustion chamber triggers combustion before the actual ignition point. Potential candidates are the hot exhaust valve, the spark plug, sealing parts and deposits on these parts as well as the surfaces enclosing the combustion chamber. The flame acts uncontrolled on the components, causing the temperature in the piston crown to increase sharply and reach the melting point temperature of the piston material after just a few seconds of uninterrupted glow ignition.

On engines with a predominantly hemispherical combustion chamber this causes holes in the piston crown, which usually occur on an extension of the spark plug axis.

On combustion chambers with relatively large quenching areas between the piston crown and the cylinder head, the piston top land usually melts at the point in the quenching area (see glossary) subjected to the greatest load. This often continues down to the oil control ring and into the interior of the piston.

Knocking combustion, which causes high surface temperatures on individual parts of the combustion chamber, can also lead to glow ignition.

Additional information for 2. Knocking combustion:

When the combustion is knocking, the ignition is triggered in the normal manner via the spark from the spark plug. The flame front expanding from the spark plug generates pressure waves, which trigger critical reactions in the unburned gas. As a result, self-ignition takes place simultaneously at many points in the residual gas mixture. This in turn causes the combustion speed to increase by a factor of 10–15, and the pressure increase per degree of the crankshaft and the pressure peak also rise substantially. In addition, very high frequency pressure oscillations are formed in the expansion stroke. The temperature of the surfaces enclosing the combustion chamber also increases considerably. Combustion chambers that have been burned clean of any residue are an unmistakeable indicator of combustion knocking.

On most engines, slight temporary knocking does not cause any damage, even over prolonged periods of time.

More severe and longer-lasting knocking causes piston material to be eroded from the piston top land and the piston crown. The cylinder head and the cylinder head gasket can also sustain damage in a similar way. Parts in the combustion chamber (e.g. the spark plug) can heat up so much in the process that glow ignition (pre-ignition) can take place in conjunction with overheating on the piston (i.e. material is melted on or removed by melting).

Severe continuous knocking will cause fractures in the ring land and the skirt after just a short time. This usually occurs without any material being melted on or removed by melting and without seizure marks.

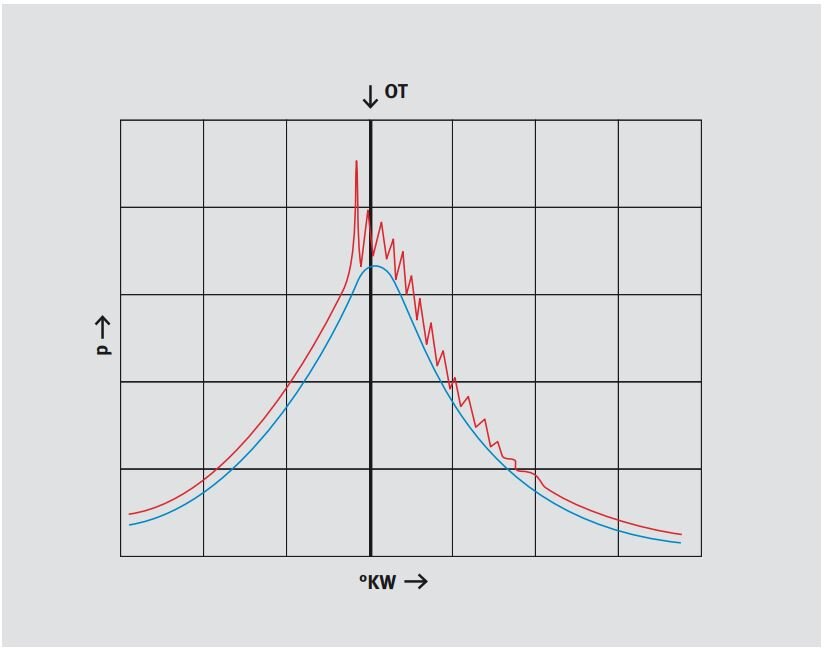

Fig. 1 shows the pressure curve in the combustion chamber. The blue curve shows the pressure curve for normal combustion. The red curve shows the pressure curve for knocking combustion, and pressure peaks occur in this case.

Additional information for 3. Fuel flooding:

An excessively rich mixture, gradual loss of compression pressure and ignition malfunctions will generate incomplete combustion with concurrent fuel flooding. The lubrication of the pistons, piston rings and cylinder running surfaces becomes ineffective. The consequence is mixed friction with wear and increased oil consumption as well as seizure marks.

In the case of glow ignition, a part that is glowing in the combustion chamber triggers combustion before the actual ignition point. Potential candidates are the hot exhaust valve, the spark plug, sealing parts and deposits on these parts as well as the surfaces enclosing the combustion chamber. The flame acts uncontrolled on the components, causing the temperature in the piston crown to increase sharply and reach the melting point temperature of the piston material after just a few seconds of uninterrupted glow ignition.

On engines with a predominantly hemispherical combustion chamber this causes holes in the piston crown, which usually occur on an extension of the spark plug axis.

On combustion chambers with relatively large quenching areas between the piston crown and the cylinder head, the piston top land usually melts at the point in the quenching area (see glossary) subjected to the greatest load. This often continues down to the oil control ring and into the interior of the piston.

Knocking combustion, which causes high surface temperatures on individual parts of the combustion chamber, can also lead to glow ignition.

Additional information for 2. Knocking combustion:

When the combustion is knocking, the ignition is triggered in the normal manner via the spark from the spark plug. The flame front expanding from the spark plug generates pressure waves, which trigger critical reactions in the unburned gas. As a result, self-ignition takes place simultaneously at many points in the residual gas mixture. This in turn causes the combustion speed to increase by a factor of 10–15, and the pressure increase per degree of the crankshaft and the pressure peak also rise substantially. In addition, very high frequency pressure oscillations are formed in the expansion stroke. The temperature of the surfaces enclosing the combustion chamber also increases considerably. Combustion chambers that have been burned clean of any residue are an unmistakeable indicator of combustion knocking.

On most engines, slight temporary knocking does not cause any damage, even over prolonged periods of time.

More severe and longer-lasting knocking causes piston material to be eroded from the piston top land and the piston crown. The cylinder head and the cylinder head gasket can also sustain damage in a similar way. Parts in the combustion chamber (e.g. the spark plug) can heat up so much in the process that glow ignition (pre-ignition) can take place in conjunction with overheating on the piston (i.e. material is melted on or removed by melting).

Severe continuous knocking will cause fractures in the ring land and the skirt after just a short time. This usually occurs without any material being melted on or removed by melting and without seizure marks.

Fig. 1 shows the pressure curve in the combustion chamber. The blue curve shows the pressure curve for normal combustion. The red curve shows the pressure curve for knocking combustion, and pressure peaks occur in this case.

Additional information for 3. Fuel flooding:

An excessively rich mixture, gradual loss of compression pressure and ignition malfunctions will generate incomplete combustion with concurrent fuel flooding. The lubrication of the pistons, piston rings and cylinder running surfaces becomes ineffective. The consequence is mixed friction with wear and increased oil consumption as well as seizure marks.

Abnormal combustion on diesel engines

In order to ensure that the combustion process is optimised, use of an injection nozzle with extremely fine fuel atomisation and precise delivery and correct start of injection are also essential in addition to the basic requirement that the engine is mechanically in perfect working order. This is the only way to ensure that the injected fuel can ignite with a minimum ignition delay and, under normal pressure conditions, burn completely. Here too a distinction is made into three serious types of abnormal combustion:

1. Ignition delay

2. Incomplete combustion

3. Injection nozzles dripping after injection

Additional information for 1. Ignition delay:

The fuel will only ignite after a certain delay (ignition delay) if:

The degree of atomisation depends only on the condition of the injection nozzle. An injection nozzle that works perfectly as tested with a nozzle tester can become jammed during installation or due to thermal stress such that it no longer atomises the fuel properly during operation.

The compression temperature depends on the compression pressure and therefore on the mechanical condition of the engine. On a cold engine there is always a certain ignition delay. During compression, the cold cylinder walls absorb a lot of heat from the (colder) intake air. As a result, the compression temperature present at the start of injection is not sufficient to immediately ignite the injected fuel. The required ignition temperature is not reached until the compression reaches a more advanced stage, at which point the fuel injected so far ignites suddenly. This causes a steep, explosive pressure increase that generates a noise and causes a sharp increase in the temperature of the piston crown. This can result in fractures, for example in the ring lands of the piston as well as heat stress cracks on the piston crown.

Additional information for 2. Incomplete combustion:

If the fuel does not reach the combustion chamber at the right time, or if it is not properly atomised, then the short period of time available is not enough to ensure complete combustion. The same happens if there is not enough oxygen (i.e. intake air) in the cylinder. The causes for this could be a blocked air filter, intake valves not opening correctly, turbocharger faults or wear on the piston rings and the valves. Unburned fuel partly condenses on the cylinder surfaces, where it adversely affects or destroys the lubricating film. Within a very short space of time this results in severe wear or seizure on the cylinder sliding surfaces, the piston ring running surfaces and ultimately also the piston skirt surfaces. This means that the engine will start to consume more oil and lose power.

Additional information for 3. Injection nozzles dripping after injection:

The injection nozzle may open again at the end of injection as a result of pressure fluctuations. These pressure fluctuations may come from the pressure valve of the fuel injection pump, the lines or the injection nozzles. To prevent this incorrect injection, the pressure in the system is reduced by a certain amount by the pressure valve of the fuel injection pump. If the injection pressure of the injection nozzles is set too low or if the pressure cannot be reliably maintained (mechanical injection nozzles), then it is possible that, despite this pressure reduction, the injection nozzles could still open several times in sequence after the end of injection. Injection nozzles that leak or drip after injection also cause an uncontrolled delivery of fuel into the combustion chamber. The uncontrolled injected fuel in both cases ends up unburned on the piston crown due to the lack of oxygen. There the fuel burns under quite high temperatures and heats local areas of the piston material so strongly that parts of the piston can be torn away from the surface under the effects of inertia force and erosion. This results in substantial amounts of material being carried away or washed away erosively on the piston crown.

1. Ignition delay

2. Incomplete combustion

3. Injection nozzles dripping after injection

Additional information for 1. Ignition delay:

The fuel will only ignite after a certain delay (ignition delay) if:

- it is not atomised finely enough,

- if it is injected into the cylinder at the wrong time,

- if the combustion temperature is not yet high enough at the start of injection.

The degree of atomisation depends only on the condition of the injection nozzle. An injection nozzle that works perfectly as tested with a nozzle tester can become jammed during installation or due to thermal stress such that it no longer atomises the fuel properly during operation.

The compression temperature depends on the compression pressure and therefore on the mechanical condition of the engine. On a cold engine there is always a certain ignition delay. During compression, the cold cylinder walls absorb a lot of heat from the (colder) intake air. As a result, the compression temperature present at the start of injection is not sufficient to immediately ignite the injected fuel. The required ignition temperature is not reached until the compression reaches a more advanced stage, at which point the fuel injected so far ignites suddenly. This causes a steep, explosive pressure increase that generates a noise and causes a sharp increase in the temperature of the piston crown. This can result in fractures, for example in the ring lands of the piston as well as heat stress cracks on the piston crown.

Additional information for 2. Incomplete combustion:

If the fuel does not reach the combustion chamber at the right time, or if it is not properly atomised, then the short period of time available is not enough to ensure complete combustion. The same happens if there is not enough oxygen (i.e. intake air) in the cylinder. The causes for this could be a blocked air filter, intake valves not opening correctly, turbocharger faults or wear on the piston rings and the valves. Unburned fuel partly condenses on the cylinder surfaces, where it adversely affects or destroys the lubricating film. Within a very short space of time this results in severe wear or seizure on the cylinder sliding surfaces, the piston ring running surfaces and ultimately also the piston skirt surfaces. This means that the engine will start to consume more oil and lose power.

Additional information for 3. Injection nozzles dripping after injection:

The injection nozzle may open again at the end of injection as a result of pressure fluctuations. These pressure fluctuations may come from the pressure valve of the fuel injection pump, the lines or the injection nozzles. To prevent this incorrect injection, the pressure in the system is reduced by a certain amount by the pressure valve of the fuel injection pump. If the injection pressure of the injection nozzles is set too low or if the pressure cannot be reliably maintained (mechanical injection nozzles), then it is possible that, despite this pressure reduction, the injection nozzles could still open several times in sequence after the end of injection. Injection nozzles that leak or drip after injection also cause an uncontrolled delivery of fuel into the combustion chamber. The uncontrolled injected fuel in both cases ends up unburned on the piston crown due to the lack of oxygen. There the fuel burns under quite high temperatures and heats local areas of the piston material so strongly that parts of the piston can be torn away from the surface under the effects of inertia force and erosion. This results in substantial amounts of material being carried away or washed away erosively on the piston crown.