Leaking water pumps caused by incorrect coolant

Back to search

Information on diagnostics

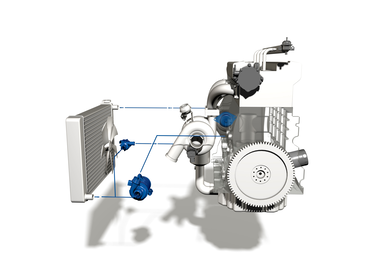

Can the wrong type of coolant agent cause damage to the water pump?

Yes, using the wrong coolant agent can have a major impact on the operational safety of coolant pumps. In the majority of cases, they will start to leak and therefore lose coolant agent.

Situation

Using the wrong coolant in the water pumps has a significant effect on operational safety.

Cause of damage

Primarily, corroded solid particles, which come off the surface of the cooling system, destroy the mechanical face seals of the water pumps. The main cause of this corrosion inside the cooling system is insufficient corrosion protection from the coolant.

Remedy

Only use the coolant approved by the manufacturer for mixing the coolant. Avoid water with a high hardness level (>20°dH) or water from sea water desalination plants.

Ensure that the coolant is always mixed in a separate container outside the cooling system.

For sufficient and outstanding corrosion protection all year round, the mix ratio of coolant and water is important for ensuring the proper functioning and service life of the water pump. For safety reasons, we recommend a mix ratio of 50:50.

Using the wrong coolant in the water pumps has a significant effect on operational safety.

Cause of damage

Primarily, corroded solid particles, which come off the surface of the cooling system, destroy the mechanical face seals of the water pumps. The main cause of this corrosion inside the cooling system is insufficient corrosion protection from the coolant.

Remedy

Only use the coolant approved by the manufacturer for mixing the coolant. Avoid water with a high hardness level (>20°dH) or water from sea water desalination plants.

Ensure that the coolant is always mixed in a separate container outside the cooling system.

For sufficient and outstanding corrosion protection all year round, the mix ratio of coolant and water is important for ensuring the proper functioning and service life of the water pump. For safety reasons, we recommend a mix ratio of 50:50.

Corrosion in the cooling system is caused by using out-of-date or unsuitable coolant. Due to this connection, heavily corroded water pumps are not covered by the warranty.