Cylinders and cylinder liners Part 2

Information on diagnostics

Signs of corrosion visible on the outer diameter of the cylinder liner? Shiny, uneven running patterns visible on the sliding surfaces in the cylinders? What are the possible consequences of defective turbochargers in the cylinder and on the piston? What causes piston seizures on the thrust and anti-thrust side? Find out the key information here.

Irregular sliding surface wear

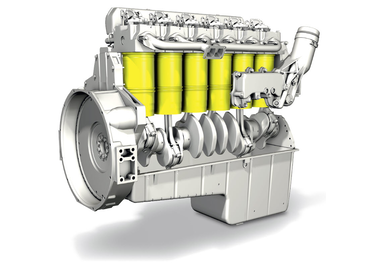

- Corrosion on the outside diameter of the cylinder liner (Fig. 1).

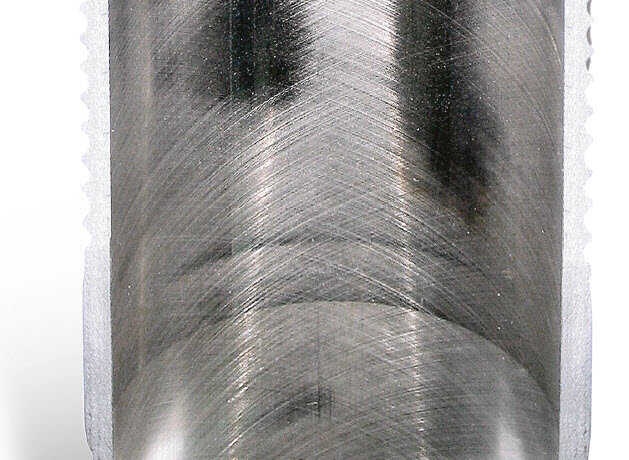

- Uneven wear pattern with individual bright areas on the cylinder surface (Fig. 2).

- Piston undamaged.

- Oil loss at the sealing points, in particular the radial oil seals.

Damage assessment

Bright irregular running patterns on the sliding surfaces in the cylinders always indicate cylinder distortion. Wet or dry cylinder liners can be distorted immediatelyafter installation.

If the cylinder bores are distorted the piston rings cannot provide a perfectly tight seal against oil or combustion gases. The oil escapes past the rings into the combustion chamber, where it is burned. The increasing quantities of combustion gases streaming past the piston cause the pressure in the crankcase to rise. This overpressure causes oil loss at sealing points around the engine, particularly at the radial oil seals. Furthermore, oil is forced through the valve guides into the intake and exhaust ducts, from where it is then burned by the engine or eliminated.

Possible causes for the damage

- With dry cylinder liners, significant unevenness is often caused by contact corrosion in the counter bores in the engine block (contact corrosion, Fig. 1). In this case the cylinder counter bore should be cleaned carefully. If this does not rectify the problem, then the cylinder counter bores should be reworked, and afterwards a cylinder liner with outside oversize* should be installed. The cylinder liners have thin walls and must be able to make contact across their full length and width. If this is not the case then the cylinder liners will already become deformed on installation in the counter bores. This deformation becomes more pronounced during operation. With dry cylinder liners, a distinction is made between press-fit and slip-fit types. Press-fit cylinder liners are pressed into the engine block and need to be bored and honed after being pressed in. Slip-fit cylinder liners are already finished off and only need to be slipped into the counter bore. Due to the clearance between the cylinder liner and the cylinder counter bore, this type of liner has a greater tendency to problems with distortion and corrosion than press-fit cylinder liners.

- Uneven or incorrect tightening of the cylinder head bolts.

- Uneven engine block and cylinder head mating surfaces.

- Dirty or distorted threads on the cylinder head bolts.

- Unsuitable or incorrect cylinder head gaskets.

- Substantial cylinder distortion due to faulty liner flange contact in the housing, incorrect liner protrusion and distorted and/or a worn-out lower liner guide.

- Liner seat too loose or too tight in the housing (on dry cylinder liners).

For ribbed cylinders in particular:

- Misalignment of the ribbed cylinders. Individual ribbed cylinders must lie exactly plane-parallel to the crankcase and the cylinder head and must be at the same height.

- Incorrectly installed or missing air baffles.

- Attachment bolts touch the cylinder housing in the bores.

- Mechanical contact with the adjacent cylinder.

- Misaligned sealing surfaces at the intake and exhaust manifolds. The intake and exhaust manifolds must be pre-installed before the cylinder heads are tightened.

Reason: all sealing surfaces must be aligned; ribbed cylinders and cylinder heads must not be distorted when the manifold is tightened.

For engines without cylinder liners in particular:

Distorted cylinder bores. Certain engines tend to become distorted when the cylinder head is installed. If these engines are bored and honed as normal, problems with distortion may arise later on during operation.

Recommendation:

On engine blocks without cylinder liners where the cylinders are bored directly into the engine block, we recommend bolting a torque plate (also referred to as a honing mask) onto the mating surface of the cylinder before machining the cylinder. This torque plate has the same openings as the engine block (apart from the water ducts) and is several centimetres thick. The act of bolting on the torque plate and tightening it to the specified tightening torque creates the same tension conditions as if the cylinder head were installed. Any distortion in the cylinder bores that could arise when tightening the cylinder head bolts is therefore deliberately simulated and is therefore taken into account during machining. This ensures that the cylinder bore is (to a great extent) round and cylindrical during subsequent operation of the engine (provided that the achining is carried out properly).

Bright spots in upper sliding surface area

- Bright, bare areas with no honing structure on cylinder sliding surface (Fig. 1 and 2).

- No signs of wear on the piston.

- Oil carbon deposits on the piston top land.

- Increased oil consumption.

Damage assessment

This type of damage pattern occurs when a hard oil carbon coating forms in operation on the piston top land as a result of burned oil and combustion residue (Fig. 3). This coating has abrasive properties, which lead to increased wear in the upper part of the cylinder in operation due to the reciprocal motion and the change of bearing surfaces of the piston. The increased oil consumption is not caused by the bright spots themselves, as the polished areas do not cause noticeable out-of-roundness of the cylinder, and the piston rings can still continue to perform their sealing duties. The lubrication of the cylinder is also unaffected, as it is still possible to retain enough oil in the open graphite veins of the cylinder surface despite the loss of the honing structure. When assessing this type of damage, it is important to note that, in this case, the bright spots all coincide with points in the cylinder that come into contact with the carbonised piston top land. If the bright spots are also present at other points, then the cause for the damage is more likely to be found:

- in distortion of the cylinder (refer to the chapter entitled “Irregular sliding surface wear”),

- fuel flooding (refer to the chapter entitled “Wear on pistons, piston rings and cylinders caused by fuel flooding”),

- or ingress of dirt or contaminants (refer to the chapter entitled “Wear on pistons, piston rings and cylinder running surfaces caused by the ingress of dirt”).

Possible causes for the damage

- Excessively high ingress of engine oil into the combustion chamber due to a defective turbocharger, inadequate oil separation in the engine ventilation system, defective valve stem seals, etc.

- Overpressure in the crankcase due to increased emissions of blow-by gases or due to a defective crankcase ventilation valve.

- Inadequate cylinder finishing, resulting in increased ingress of oil into the combustion chamber (refer to the chapter entitled “Piston ring wear soon after engine reconditioning”).

- Use of non-approved engine oils or engine oils of a lower quality.

Cylinder liner crack due to hydraulic lock

- Upper area of cylinder liner displays severe damage due to a crack and seizure marks on the sliding surface (Fig. 2 and 3).

- Piston displays seizure marks on the pressure and anti-thrust sides.

- In the piston crown: bowl-shaped recess in the area of the seizure marks (Fig. 4).

Damage assessment

The cylinder liner was damaged by a hydraulic lock, which burst the cylinder liner and pressed in a dent in the piston crown.

The piston material has been squashed outwards, causing a significant restriction of the piston clearance in the cylinder bore. It is not possible to identify whether the hydraulic lock occurred while the engine was running or while it was being started.

Possible causes for the damage

- Accidental intake of water while driving through water, or as a result of larger quantities of water being splashed up by passing vehicles or vehicles in front.

- While the engine is stopped, cylinder filling up with:

- coolant due to leaks in the cylinder head gasket or cracks in components.

- fuel due to leaking injection nozzles. The residual pressure in the fuel injection system is dissipated through the leaking nozzle into the cylinder. The damage occurs when the engine is started.