Oil loss caused by ...

Information on diagnostics

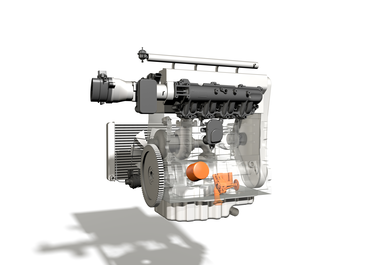

Is the car losing oil? There are many reasons for oil loss: incorrectly used sealant, foreign bodies between the sealing areas, leaking radial oil seals, sealing area faults, faulty vacuum pumps or excessively high oil pressure. Find out what to do here.

Oil loss caused by incorrect utilisation of sealants

In modern engines, liquid sealants are used to seal the outside of various systems and to seal systems to one another. However, liquid sealants may only be used for applications for which they are explicitly

specified. If other types of seal are used (metal, elastomer, soft material, etc.), liquid sealant should not be applied in addition.

The unnecessary and excessive application of liquid sealant, particularly if solid seals are in use, can cause leaks. In addition, sealant residue that comes away can cause impurities or blockages in

the oil or coolant circuit.

Attention:

When using sealants, temperature resistance and area of application must be matched to the intended purpose.

Tip:

All sealing areas must be cleaned and de-oiled using a solvent (thinner, brake cleaner, etc.) before installing the seal or applying liquid sealants. If a liquid sealant is applied to contaminated, oil-fouled surfaces, the sealing compound may not adhere to the sealing area. The sealant may be forced out of the sealing gap by the pressure of the liquid and be lost due to the sealing effect. This will result in engine oil or cooling liquid escaping.

Oil loss caused by foreign bodies between sealing areas

Foreign bodies between the seal and the component prevent correct sealing and may cause the component to become distorted. Rust, sealant and paint residue that has not been completely removed may cause similar problems.

Tip:

Foreign bodies that have been overlooked are one of the most easily avoided mistakes. All components should be carefully cleaned before assembling the engine.

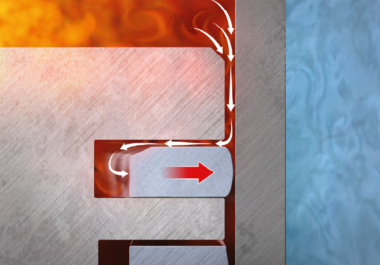

Oil loss caused by unsealed radial oil seals

Radial oil seals consist of a metal insert with an elastomer outer casing that provides the static seal to the housing. Different types of seal are used for the dynamic seal to the shaft:

- Sealing lips made of PTFE without spring support

- Elastomer membranes with sealing lips that are additionally supported by corrosion-resistant tension springs made of stainless steel

For the seal to be effective, not only must the radial oil seal be in good condition, so must the shaft surface.

Attention:

Radial oil seals made of PTFE are usually installed dry. The waiting period specified by manufacturer before starting the engine after fitting seals must be observed.

Oil loss caused by sealing area problems

If the surfaces of components are damaged (scratches, corrosion, rust, dented) or are not level, the seal may not fulfil its intended function. A gap will remain between the seal and the sealing area after joining the components through which engine oil or cooling liquid can escape.

Installation tips:

- All sealing areas must be cleaned and de-oiled using a solvent (thinner, brake cleaner, etc.) before installing the seal or applying liquid sealants.

- The sealing areas using a straightedge and any components that have been remachined must be checked.

- The surface roughness must be checked. For the seal to function correctly, the sealing areas must have the specified roughness.

Oil loss caused by faulty vacuum pumps

If vacuum pumps are defective, engine oil can enter the vacuum system by this route. This engine oil will not then be available for lubrication of the engine. Engine oil in the vacuum system will bring about malfunctions and component failure.

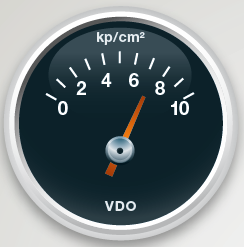

Oil loss caused by excessive oil pressure

If the oil pressure is too high, housing gaskets,

oil filters, oil coolers and pipes may leak or crack.

Reasons for excessive oil pressure:

- Wrong oil pump or pump too big

- Blocked oil filter without overflow valve

- Wrong oil filter

- Paper element in oil filter has disintegrated

- Wrong seals, outlets for engine oil missing or too small

- Plug or cleaning cloth left behind when doing repairs

- Oil feed lines and hoses blocked, kinked or constricted

- Faulty pressure control valves or pressure relief valves

- Malfunctions in the oil circuit due to using the wrong parts, e.g. wrong non-return valves or hoses

- Using engine oil with the wrong viscosity

- Old engine oil that has taken on a jellylike consistency with low ambient temperatures or frost