High-pressure / low-pressure exhaust gas recirculation

What is the difference?

How does exhaust gas recirculation work in a combustion engine or petrol engine and how does it help to reduce nitrogen oxide emissions? What is the correlation between exhaust gas temperature and fuel consumption? This article provides the answers to these questions and explains how exhaust gas recirculation valves are controlled and how this system reduces soot particulates during fuel consumption.

Exhaust gas recirculation (EGR) has proven to be a successful method of emission control. In the case of conventional highpressure EGR, exhaust gas is removed immediately after the cylinder and mixed with the intake air. Additional low-pressure EGR is now commonly used to achieve the stricter limit values as of Euro 6 / Tier 2.

But what is the difference?

The table below provides a quick overview. Further information can be found on the following pages.

| High-pressure EGR | Low-pressure EGR | |

| Inlet pressure into the EGR section | high (up to approx. 3.5 bar) | low (up to approx. 1.3 bar) |

| Inlet temperature into the EGR section | very high (up to approx. 950°C) | high (up to approx. 800°C) |

| Pressure difference Δp over the EGR section | high (up to approx. 1.5 bar) | low (up to approx. 0.3 bar) |

| Cyclical pressure fluctuations | high | low |

| Exhaust gas composition | Removal before exhaust gas after-treatment | Removal after exhaust gas after-treatment |

Exhaust gas recirculation – an overview

There are various positions for exhaust gas removal:

INTERNAL EGR

- Valve overlapping means that some exhaust gas remains in the combustion chamber or is sucked back into the cylinder from the outlet duct.

- The timing of the intake and exhaust valves is changed by means of adjustable cams.

- Exhaust gas is removed outside the cylinder head on the exhaust gas side and is fed back via lines or ducts to the fresh air side through an external valve.

- This provides the opportunity for additional exhaust gas cooling by an optional cooler with / without bypass flap.

There are two types of external EGR:

HIGH-PRESSURE EGR

The exhaust gas is

- removed immediately after the cylinders, upstream of the turbocharger turbine and

- fed back to the fresh air side after the throttle valve.

The exhaust gas is

- removed downstream of the turbocharger turbine or only after the exhaust treatment systems and

- fed back upstream of the turbocharger compressor.

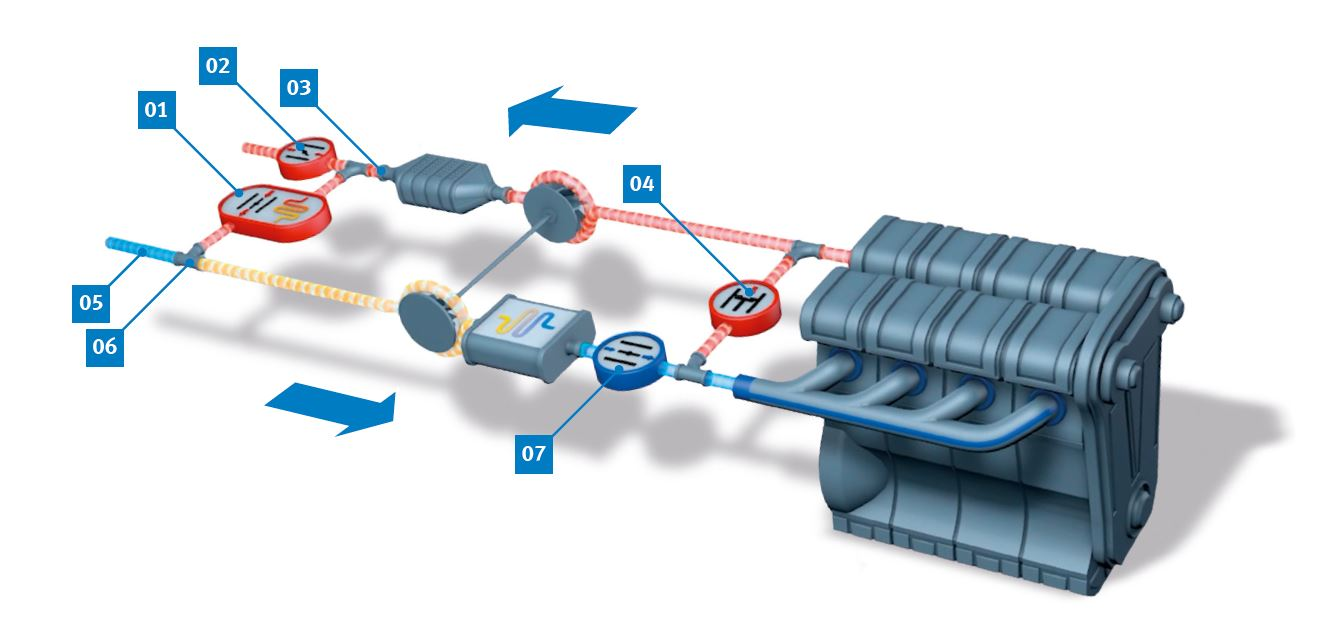

02 Low-pressure EGR valve

03 Low-pressure EGR cooler

04 Turbocharger (compressor)

05 Turbocharger (turbine)

06 Particulate filter

07 Charge air cooler

08 Throttle valve / regulating throttle

09 High-pressure EGR valve

blue: High-pressure area

green: Low-pressure area

Low-pressure EGR

The advantages of adding low-pressure EGR to high-pressure EGR include:

- Higher performance / efficiency of the turbine

- Larger EGR map

- More homogeneous mixing of exhaust gas with fresh air via the compressor

- Resulting in lower NOx and particulate emissions

- Improved EGR cooling (through EGR and charge air cooler)

The disadvantages compared to high-pressure EGR include:

- Longer paths and additional components

- Possible hazard due to soiling or damage to the turbocharger compressor, e.g. through droplet impact

High-pressure EGR is primarily used in the case of a cold start or short-term state changes, e.g. when accelerating.

The low-pressure EGR valves from Pierburg generally consist of a centrally positioned flap (“butterfly”) in an aluminium pressure die-cast housing. The integrated actuating drive usually consists of a DC electric motor and a two-stage spur gear unit. Tried-andtested assembly groups from existing throttle valve and EGR valve product lines – which have already proved their worth over years of series production – were used when designing the lowpressure valves.

The low-pressure EGR combi valve simultaneously assumes the tasks of the low-pressure EGR valve and an intake air throttle. The throttling results in a pressure gradient in relation to the intake side, causing the exhaust gas to flow into the area in front of the compressor in a controlled manner. As a combined component, the low-pressure combi valve is not only more cost-effective, but also offers the benefit of a lower weight.

Typical damage in the area of the low-pressure EGR includes:

- Leakages in the exhaust gas lines or the coolant line

- Leakages in or on the EGR cooler

- Low-pressure EGR valve leaks / does not open or close

- Electrical actuation of the servo motor defective

Exhaust gas recirculation and pierburg

Video - EXHAUST GAS RECIRCULATION (EGR) MADE EASY

We need your consent to load the YouTube service!

In order to play YouTube videos, a connection to YouTube must be established. This will also entail data processing and cookie usage by YouTube/Google (possibly also out of the USA). By clicking "Accept", you consent to this data processing and the placing of YouTube cookies on your terminal device. Your selection will be saved for future visits to this website. You may find further information under "More" and in our Data Protection Information.

Tags

Product groups

This might also interest you