Formation of partial vacuums on fluid pumps

Causes, effects, preventing faults

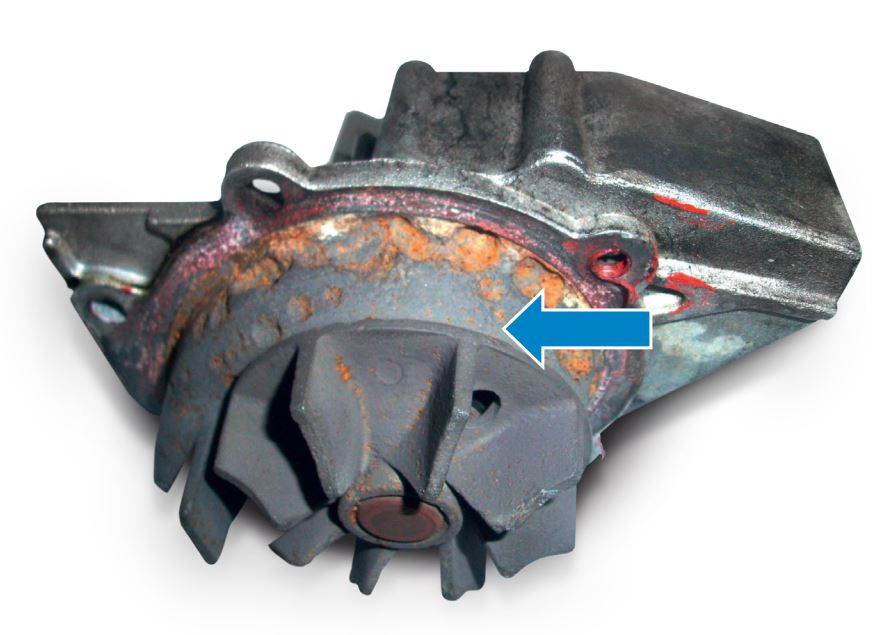

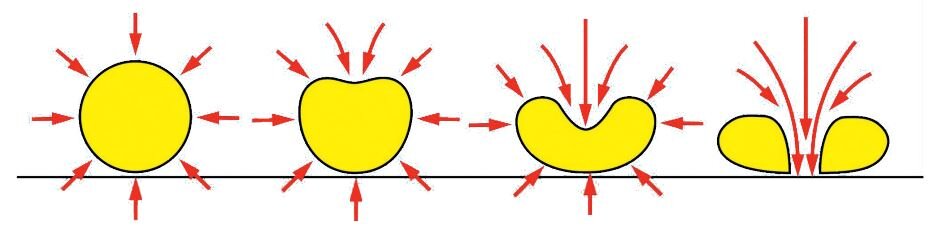

Is the pump casing broken? Is there a pressure drop and do noises occur? But what does the car’s refrigeration system have to do with this? Perhaps the wrong coolant was used? If the fluid pump casing has holes, partial vacuums forming may be the cause. The formation of partial vacuums causes damage due to bubbles, which cause holes in the top face due to pressure. During the formation of partial vacuums, vapour forms in the cavities of the fluid pump from the surrounding fluid.

The implosion of the bubbles and the resulting external pressure, the vapour pressure, makes these cavities collapse and causes faults on the pump. This article describes exactly how formation of partial vacuums can occur, the effects it has on the refrigeration system and how it can overload the engine.

Cavitation may also indicate that the water pump was not installed with due care and attention.

Cavitation is the result of:

- Maintenance errors

- Improper operating conditions

- Cooling system malfunction

- Incorrect cooling liquid

Origin of cavitation

- The boiling point of the liquid itself.

- The pressure in the liquid.

- The temperature of the liquid.

These three parameters influence one another. Please see below for the causes that govern the way in which the boiling point can be reached in an engine cooling system. The attainment of the boiling point and the occurrence of cavitation are often due to multiple causes at the same time.

Reaching the boiling point due to low operating pressure in the cooling system

- Leaking cooling system.

- Faulty or incorrect radiator filler cap – incorrect opening pressure of the pressure relief valve.

- Insufficient operating temperature of the engine – engine operation without thermostat, or thermostat with insufficient opening temperature.

- Engine operation in high mountain regions – the low ambient pressure also affects the operating pressure in the cooling system.

Reaching the boiling point due to fast movements of liquids and objects

- Local low-pressure zones on components caused by oscillation of components.

- Local low-pressure zones due to fast movements of components in liquids, particularly in pump impellers and propellers.

- High flow velocity of liquids combined with a sharp change in the direction of flow or with flow reversal. If the flow velocity is so high that the static pressure falls below the evaporation pressure of the liquid, this leads to the formation of vapour bubbles.

Cooling liquid boiling point too low

- Use of normal water without the addition of coolant agent.

- Unsuitable cooling liquid (insufficient coolant agent concentration, ageing cooling liquid).

Reaching the boiling point due to excess component temperature

Tags

Product groups

This might also interest you