Coolant: mixing ratio

If the motor vehicle’s cooling equipment is not maintained, expensive damage may occur, for example to the engine. The cooling medium, also known as radiator antifreeze or frost protection agent, is particularly important here. In a cooling loop, several litres of cooling fluid flow from the cylinder head and engine block to the cooler in the cooling equipment. What quantity is appropriate, what ratio the mixture of cooling water should have, whether the combination can be used as a dilution or concentrate and the most important rules for dealing with cooling media and water circulating pumps are described in this article.

Mixing the cooling liquid

|

Attention: Under no circumstances may water be used in the cooling system without the addition of coolant agent. |

Water and coolant agent must always be mixed outside the cooling system. Avoid pouring pure coolant agent into the cooling system in order to then top up the residual amount with water. The silicates contained in the coolant agent form a protective coating in the cooling system. If you start by filling the cooling system with pure coolant agent, an excessively thick protective coating will form due to the high concentration at the more low-lying surfaces of the cooling system. In this case, the content of silicate is no longer sufficient in order to guarantee the protective coating across the entire surface of the cooling system.

Calcification is formed in the cooling system, for example, if a leaking cooling system is constantly refilled with water. If water is topped up, new hardeners are added with each filling procedure. These are deposited in the cooling system in the form of scale deposits (calcium carbonate and magnesium carbonate) and impede the heat exchange. Loose scale particles lead to abrasive wear of the sliding ring seal and failure of the water pump.

Tip:

If only highly calciferous water is available for the purpose of mixing the cooling liquid, you can boil the water in order to remove some of the substances that promote hardening. This breaks down the carbonate hardness into scale deposits, meaning that it is no longer able to form any deposits in the cooling system.

*Distilled water is very low in minerals. As a result, even experts frequently have doubts as to whether this water should be used for the purpose of mixing the cooling liquid. The strong corrosion protection provided by pure coolant agent means that the use of distilled water does not have any negative effects.

The most important rules for handling

water pumps and cooling liquid

- Use only specified cooling liquid.

- Observe the change intervals of the cooling liquid.

- Defective or damaged viscous couplings or fan blades must be replaced.

- Only use liquid housing sealants where these are specified.

- You must adhere to the specified belt tension.

- It is essential that you replace and adjust tension pulleys and automatic belt tensioners in accordance with the manufacturer‘s instructions.

- Ensure venting of the cooling system.

- The pump shafts of new water pumps must never be turned back and forth by hand.

- Do not use any worn, damaged or bent pulleys.

- No radiator sealant additives may be mixed into the cooling liquid.

- Never ever operate water pumps without cooling liquid.

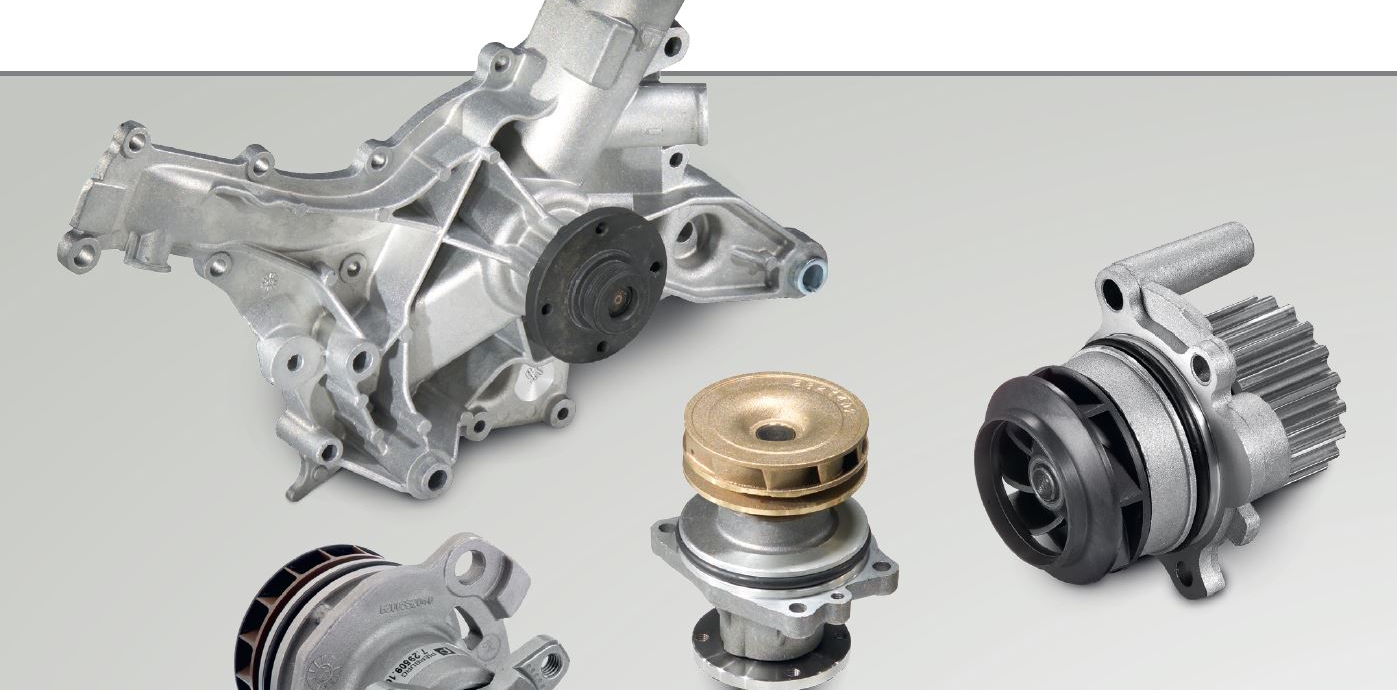

Video - WATER PUMPS/ COOLANT PUMPS - BASIC INFORMATION - MOTORSERVICE GROUP

We need your consent to load the YouTube service!

In order to play YouTube videos, a connection to YouTube must be established. This will also entail data processing and cookie usage by YouTube/Google (possibly also out of the USA). By clicking "Accept", you consent to this data processing and the placing of YouTube cookies on your terminal device. Your selection will be saved for future visits to this website. You may find further information under "More" and in our Data Protection Information.

Tags

Product groups

This might also interest you