Machining errors

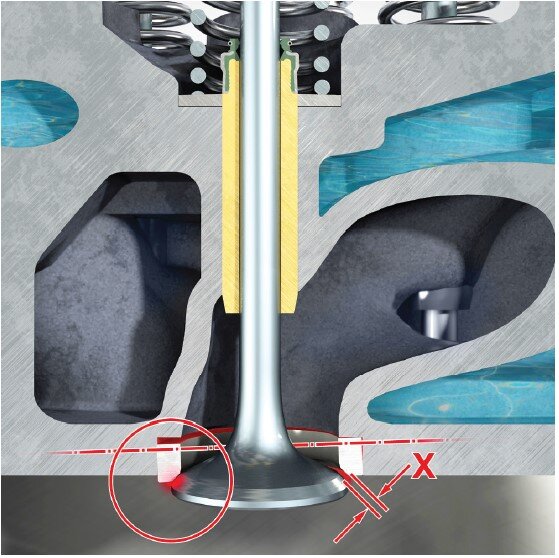

Misalignment at the valve seat insert or valve guide

Cause:

Non-centric remachining of the valve seat or guide.

Non-centric remachining of the valve seat or guide.

Consequence:

The valve fails to close properly, overheats and burns through in the seat area. Fatigue fractures in the area of the fillet may also occur as a result of the unilateral stress of the valve head.

The valve fails to close properly, overheats and burns through in the seat area. Fatigue fractures in the area of the fillet may also occur as a result of the unilateral stress of the valve head.

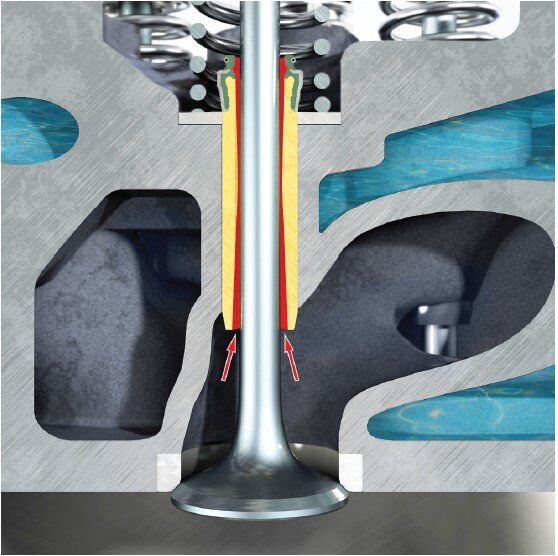

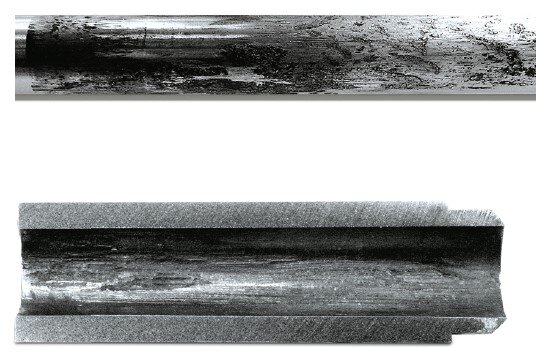

Excessive valve guide clearance

Cause:

The valve guide clearance is too large due to excessive wear of the valve guides or due to excessive reaming during repair.

The valve guide clearance is too large due to excessive wear of the valve guides or due to excessive reaming during repair.

Consequence:

The influx of hot gases can cause significant carbon deposits in the area of the stem guide. The valve becomes stiff and fails to close properly, with overheating of the seat occurring as a result (burns or shot channels).

The influx of hot gases can cause significant carbon deposits in the area of the stem guide. The valve becomes stiff and fails to close properly, with overheating of the seat occurring as a result (burns or shot channels).

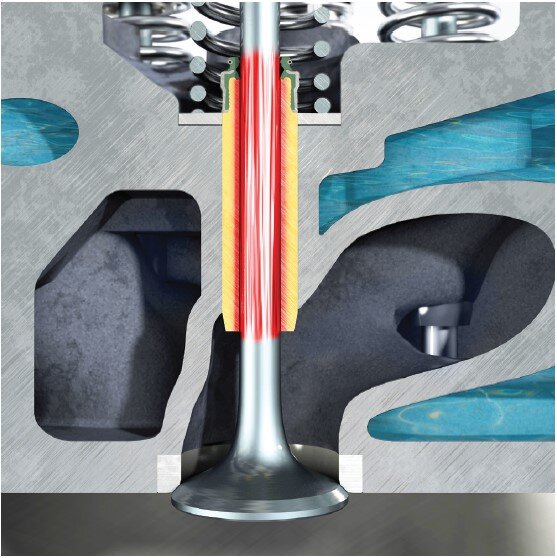

Insufficient valve guide clearance

Cause:

The guide diameter has been dimensioned too small during replacement of the valve guides.

The guide diameter has been dimensioned too small during replacement of the valve guides.

Consequence:

Inadequate lubrication, stiffness and seizures of the valve stem in the guide. Consequential damage such as overheating of the valve head or seat area can occur.

Inadequate lubrication, stiffness and seizures of the valve stem in the guide. Consequential damage such as overheating of the valve head or seat area can occur.