Installation and adjustment errors

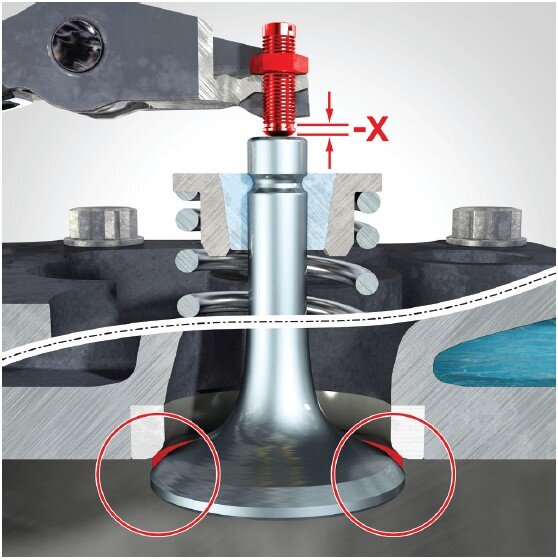

Incorrect valve clearance settings

Cause:

The valve clearance has been set too tight or the maintenance intervals have been exceeded.

The valve clearance has been set too tight or the maintenance intervals have been exceeded.

Consequence:

The value no longer closes properly. Combustion gases flow past the valve seat and heat up the valve head. This causes the valve head to overheat and burns through in the seat area.

The value no longer closes properly. Combustion gases flow past the valve seat and heat up the valve head. This causes the valve head to overheat and burns through in the seat area.

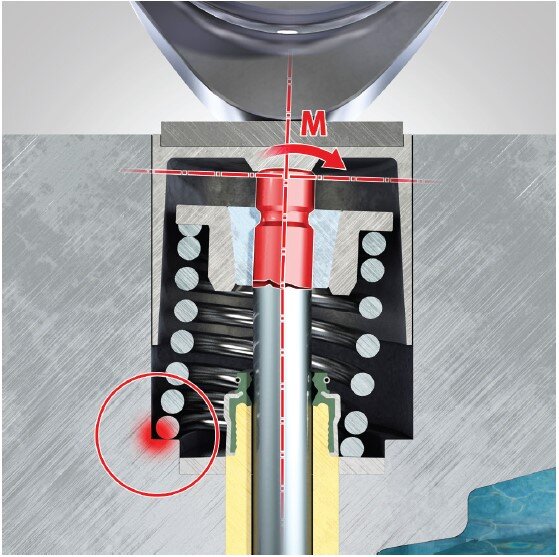

Incorrectly installed valve springs

Cause:

The spring was not inserted correctly during installation. The tilted spring has caused a lateral bending moment (M) on the valve stem.

The spring was not inserted correctly during installation. The tilted spring has caused a lateral bending moment (M) on the valve stem.

Consequence:

The resultant alternating bending stress ultimately caused a fracture of the valve stem face and destroyed the valve guide.

The resultant alternating bending stress ultimately caused a fracture of the valve stem face and destroyed the valve guide.

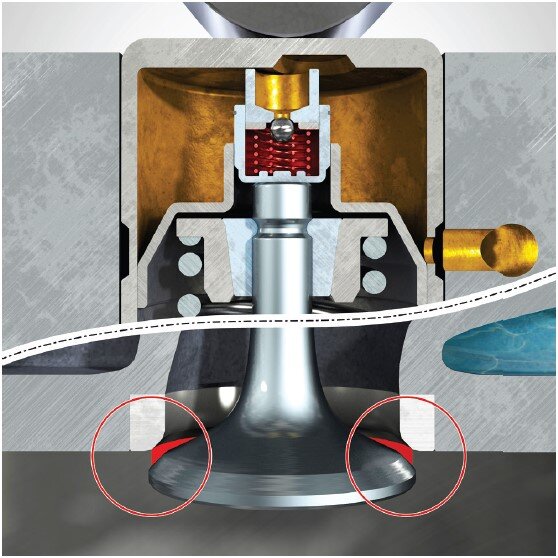

Incorrectly installed valve springs

Cause:

After installation of the tappets, the minimum required waiting time before starting the engine (at least 30 mins) was not observed. As a result, the excess oil in the working area of the tappets did not have enough time to escape.

After installation of the tappets, the minimum required waiting time before starting the engine (at least 30 mins) was not observed. As a result, the excess oil in the working area of the tappets did not have enough time to escape.

Consequence:

If the engine is started prematurely, the valves strike against the piston and can bend or break.

If the engine is started prematurely, the valves strike against the piston and can bend or break.