Dirt

Intake of dirt in the engine is one of the most frequent reasons for early wear on the engine and, consequently, also on the piston rings. There are two principal causes of dirt damage:

Cause 1

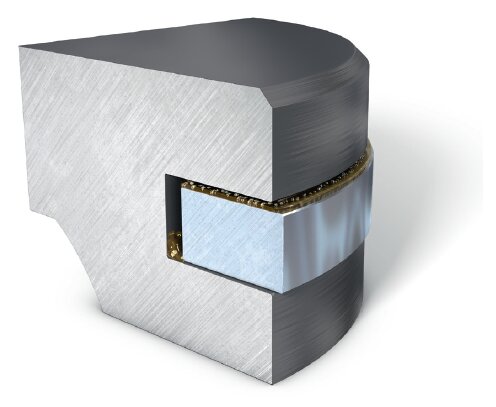

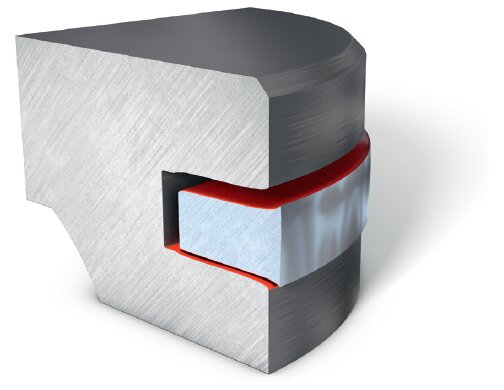

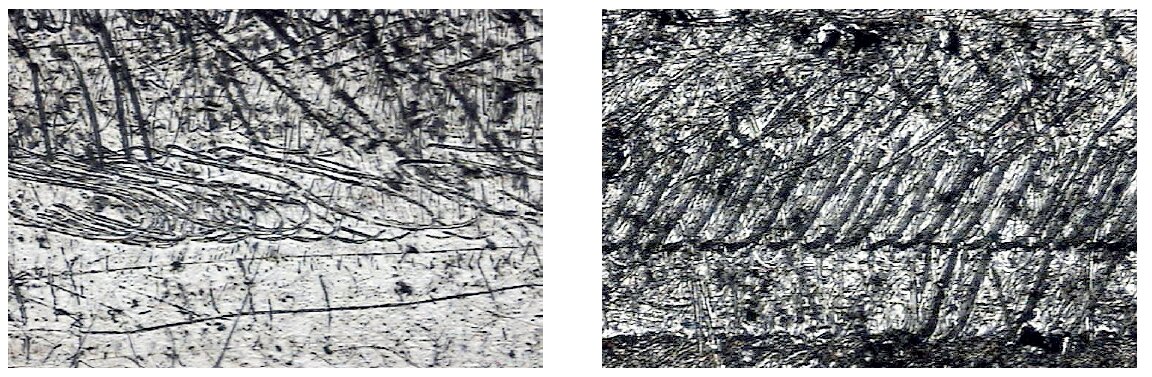

The dirt is transported into the cylinder with the intake air. This always happens when the air filter maintenance is not carried out correctly. If the vehicle is driven without an air filter or if there is a leak in the intake system and the dirt enters the combustion chamber past the air filter. The dirt in the combustion chamber also enters the piston ring grooves, where it combines with the oil to form an abrasive paste. The height of the piston rings is ground down in this case and the piston ring grooves are expanded. The wear caused by the dirt on the piston rings mainly acts on the ring sides in axial direction. In radial direction (on the sliding surface), the ring also wears due to the resulting mixed friction, but nowhere near as much as on the sides. Roller marks on the ring sides are a frequent indication of dirt in the ring grooves. The dirt, which consists mainly of fine sand, in conjunction with the rotation of the rings and the piston rocking motion, scratches characteristic patterns into the ring side.

Because the rings are mainly in contact with the bottom groove side during operation, the wear mainly occurs on the top ring side. This is also where the roller marks are found .

Cause 2

The dirt is still in the oil circuit as a result of previous damage and/or a poorly carried out repair/reconditioning. The dirt then starts to wear on the cylinder walls and pistons from the crankcase. Dirt particles also reach all bearing positions in the engine via contaminated oil circuits. Although the oil is filtered via the oil filter, the oil circuit is frequently not cleaned correctly. Dirt that is already on the clean side of the oil circuit reaches the bearing positions and results in premature wear or damage.

In the event of engine damage, the oil filter is often so heavily blocked through abrasion that the bypass valve opens. In this case, the engine oil reaches the lubricating points unfiltered. These facts are accepted in the engine design to prevent major engine damage due to complete oil loss on the bearings. Following engine damage, there are often still large amounts of dirt in the oil cooler and in its oil lines. It is therefore irresponsible to connect a new or reconditioned engine to an uncleaned oil cooler and run the engine.

|

ATTENTION If an oil cooler is contaminated as a result of engine damage, cleaning often brings minimal success. In this case, it is better to use a new oil cooler to rule out the risk of damage resulting from using the old oil cooler. |