Piston ring wear soon after engine reconditioning

DESCRIPTION OF THE DAMAGE

- No damage or wear on piston.

- Superficial inspection of piston rings reveals no wear marks, however, closer inspection reveals abnormal wear on the oil-scraping ring edges, mostly on the bottom ring edges (see magnified image).

- Tangible burr on the bottom edge of the piston ring running surface.

DAMAGE ASSESSMENT

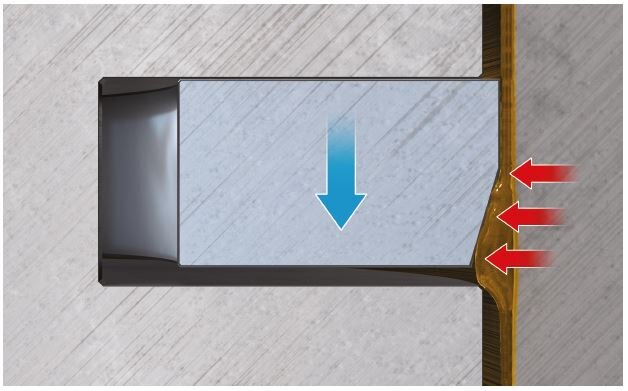

The worn piston ring edges lead to high hydrodynamic forces (Fig. 2) between the running surfaces of the piston rings and the cylinder running surface as a result of the formation of an oil wedge.

The piston rings float on the oil film during the upward/ downward motion of the piston and are lifted off slightly from the cylinder running surface. In this way, an increased quantity of lubricating oil reaches the combustion chamber where it is burned.

POSSIBLE CAUSES FOR THE DAMAGE

The burring is caused if the piston rings are refitted in less than ideal conditions after the engine reconditioning. The main reasons are insufficient or inappropriate cylinder finishing. If blunt honing stones are used for finish honing or excessive pressure is applied during honing, burrs and elevations form on the cylinder wall. These metal edges are folded over in the direction of machining (Fig. 3). This is referred to as the “peak folding formation” and causes increased friction during the running-in phase, preventing engine oil from becoming deposited in the fine graphite veins.

If these burrs are not removed in a final machining process referred to as plateau honing, this will result in premature wear at the piston ring edges during the running-in phase. The piston rings then take on the undesired duty of wearing away the folded peaks and cleaning the graphite veins. However, this leads to wear on the piston ring edges and the formation of burrs. From experience, burrs created in this way on the piston ring edge can only be run off with great difficulty. The damaged piston rings need to be replaced.

A second set of piston rings installed as replacement rings will encounter much better, virtually normal operating conditions. This is because the first set of piston rings will have removed most of the disadvantageous edge layer on the cylinder running surface (the “peak folding formation”) through wear. The oil consumption will return to normal levels after replacing the piston rings. In many cases this is incorrectly attributed to poor-quality materials in the first piston rings that were installed.

If these burrs are not removed in a final machining process referred to as plateau honing, this will result in premature wear at the piston ring edges during the running-in phase. The piston rings then take on the undesired duty of wearing away the folded peaks and cleaning the graphite veins. However, this leads to wear on the piston ring edges and the formation of burrs. From experience, burrs created in this way on the piston ring edge can only be run off with great difficulty. The damaged piston rings need to be replaced.

A second set of piston rings installed as replacement rings will encounter much better, virtually normal operating conditions. This is because the first set of piston rings will have removed most of the disadvantageous edge layer on the cylinder running surface (the “peak folding formation”) through wear. The oil consumption will return to normal levels after replacing the piston rings. In many cases this is incorrectly attributed to poor-quality materials in the first piston rings that were installed.

The microscopic enlargement in Fig. 4 shows the bent-over peaks through a section of the cylinder surface after the disadvantageous honing of the cylinder running surface (peak folding). Fig. 5 shows the surface after plateau honing. The burrs and peaks have been mostly removed, and the graphite veins have been exposed. The piston rings will encounter good conditions for running-in and should therefore provide a long service life. Hone-brushing the surface to create the plateau finish delivers particularly good results.

Side info