Piston damage caused by broken piston pin circlips

DESCRIPTION OF THE DAMAGE 1

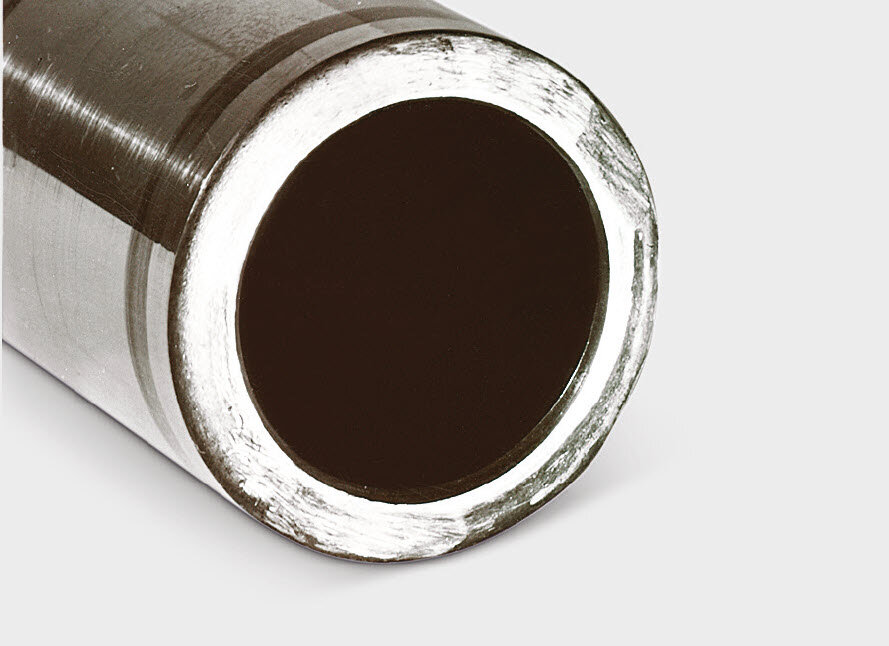

- End of the piston pin bore on both sides of the piston suffered serious damage, in some places as far as the ring zone (Fig. 1).

- Circlip jumped out of the retaining groove and broke into fragments.

- Second circlip damaged.

- Due to the lack of retention, the piston pin has wandered outwards towards the cylinder running surface.

- Front face of the piston pin worn to a convex shape due to prolonged contact with the cylinder running surface (Fig. 2).

- Asymmetrical running pattern of the piston.

DESCRIPTION OF THE DAMAGE 2

- Asymmetrical piston wear pattern (Fig. 4).

- Piston pin boss and piston pin broken (Fig. 5 and 6).

- Pin bore hammered out in the area of the circlips.

DAMAGE ASSESSMENT

Whether as wire circlips or Seeger-type circlips, the piston pin circlips are only forced out or hammered out in operation by means of axial thrust of the piston pin. This is based on the requirement that the circlip has been correctly inserted and has not been damaged.

Axial thrust in the piston pin always occurs when the piston pin axis is not parallel to the crankshaft axis. This is the case when a bent connecting rod leads to the piston running at a considerable angle. The reciprocating movements result in alternating axial thrust, which effectively hammers out the circlip. Once the circlip has jumped out, it is then clamped between the piston pin moving in an outwards direction, the piston and the cylinder running surface.

There, it is worn away and finally breaks into several fragments. Within a short space of time the fragment inertia forces hammer into the piston material as the piston moves up and down (Fig. 2). Individual fragments also move through the hollow piston pin and cause corresponding destruction on the opposite side of the piston.

Axial thrust in the piston pin always occurs when the piston pin axis is not parallel to the crankshaft axis. This is the case when a bent connecting rod leads to the piston running at a considerable angle. The reciprocating movements result in alternating axial thrust, which effectively hammers out the circlip. Once the circlip has jumped out, it is then clamped between the piston pin moving in an outwards direction, the piston and the cylinder running surface.

There, it is worn away and finally breaks into several fragments. Within a short space of time the fragment inertia forces hammer into the piston material as the piston moves up and down (Fig. 2). Individual fragments also move through the hollow piston pin and cause corresponding destruction on the opposite side of the piston.

POSSIBLE CAUSES FOR THE DAMAGE

- Axial thrust of the piston pin during engine operation caused by:

- Bending or twisting of the connecting rod.

- Connecting rod eye bored at an angle (axes not parallel).

- Cylinder axis not perpendicular to crankshaft axis.

- Excessive connecting rod bearing clearance, particularly in conjunction with asymmetrical connecting rods.

- Connecting rod pins not parallel with crankshaft axis (machining fault).

- Use of old or damaged circlips.

- Improperly installed circlips.