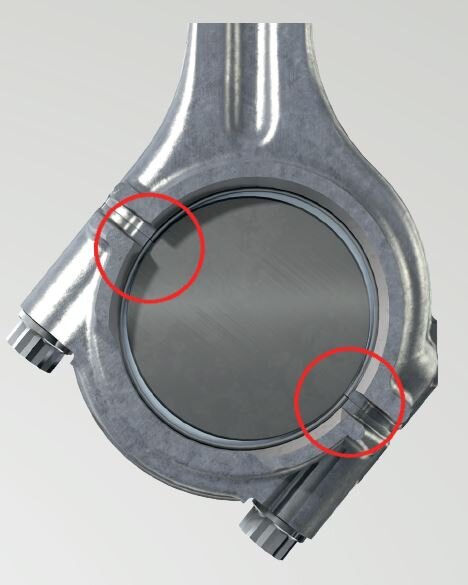

Two-sided wear on areas of the separation planes

DESCRIPTION OF THE DAMAGE

- Significant wear marks in the area of both reliefs on the upper and lower shell

- Crowns of the bearing shells significantly less worn

- In severe cases: signs of material fatigue and initial rubbing marks visible

Very pronounced wear marks can be recognised on both sides in the area of the separation planes. The crown / main load area of the bearing shell is, however, considerably less worn.

DAMAGE ASSESSMENT

If the bearing shells in this area carry weight, the fault is severe. This appearance can be caused by a vertical oval bore. This reduces the bearing clearance in the area of the parting face meaning that the lubricating film is not fully stable and mixed friction occurs in the reliefs. If the shortage of lubrication continues, the temperature increases due to the frictional heat that results. The shortage of lubrication continues to intensify due to the increasing temperature level and the process reinforces itself until the first initial rubbing marks occur and fatigue damage occurs in this area due to increased surface pressure.

POSSIBLE CAUSES FOR THE DAMAGE

- Oval deformation of the bearing bore due to thermal or mechanical stress

- Connecting rod with oval connecting rod eye – connecting rods that have already been used have been reinstalled without the reworking required

- Wrong bolt tightening when boring the bore

Remedy

- Check stress on the bearing bore

- Check bore: dimensions, roundness, cylindricity, surface must be within certain tolerances – rework used parts before reinstalling if necessary

- Tighten bolts in accordance with the manufacturer‘s specifications with regard to tightening torques and the tightening sequence