One-sided edge wear

DESCRIPTION OF THE DAMAGE

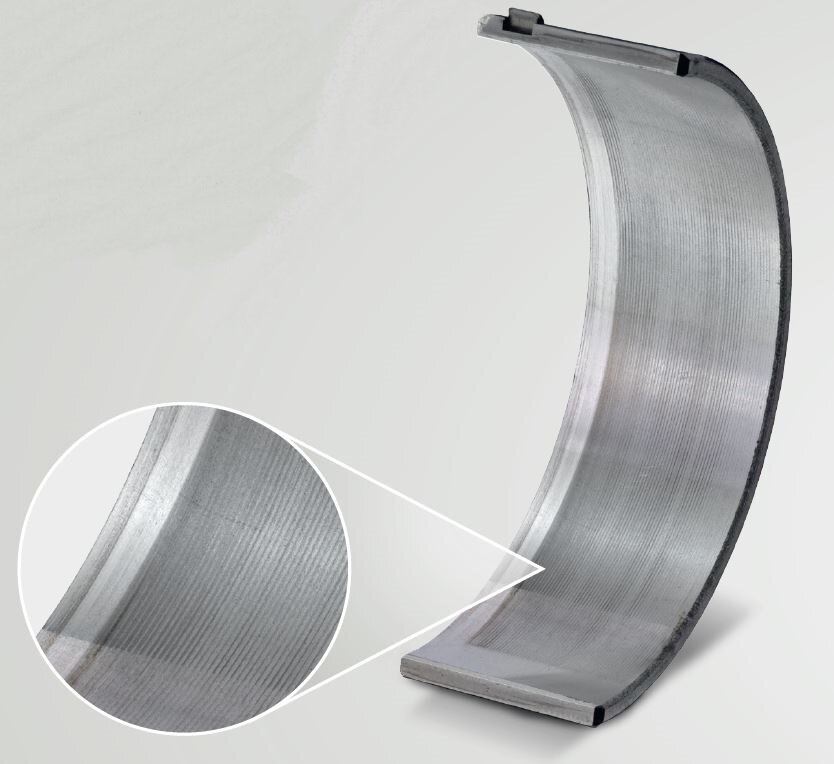

- Bright, light stripes of wear on one side at the edge of the bearing

- Identifiable signs of material fatigue or initial rubbing marks possible in the area of the edge wear in severe cases

- Overheating phenomena such as discolouration due to thermal stress or carbon deposits in the area of the edge wear on the bearing back

One-sided worn bearing edge is visible. The wear occurs in the form of adaptive run-in wear. The function of the bearing is not impaired.

DAMAGE ASSESSMENT

The lubrication gap at the bearing edge is too low, meaning that the lubricating film is not fully stable and mixed friction occurs locally. If the shortage of lubrication continues, the temperature •increases due to the frictional heat that results. This could result in overheating damage such as dark discolouration of the bearing back. The shortage of lubrication continues to intensify due to the increasing temperature level and the process reinforces itself until the first initial rubbing marks occur and fatigue damage occurs due to increased surface pressure.

Depending on the intensity of the wear at the bearing edges, this can be considered as completely normal. During operation, the crankshaft is subject to bending, which above all has an effect on the outer main bearings. The outer bearings therefore demonstrate more pronounced edge wear.

Depending on the intensity of the wear at the bearing edges, this can be considered as completely normal. During operation, the crankshaft is subject to bending, which above all has an effect on the outer main bearings. The outer bearings therefore demonstrate more pronounced edge wear.

POSSIBLE CAUSES FOR THE DAMAGE

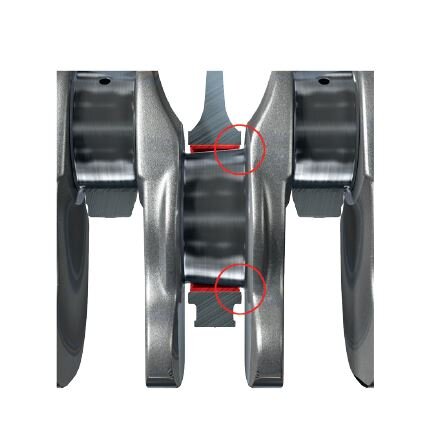

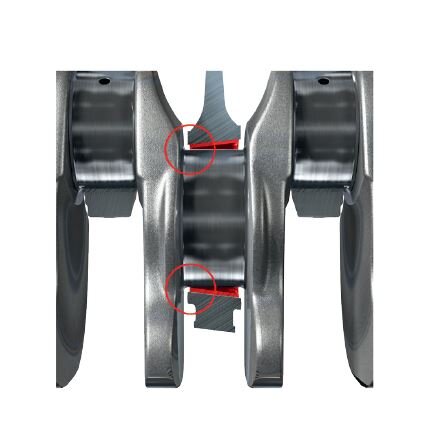

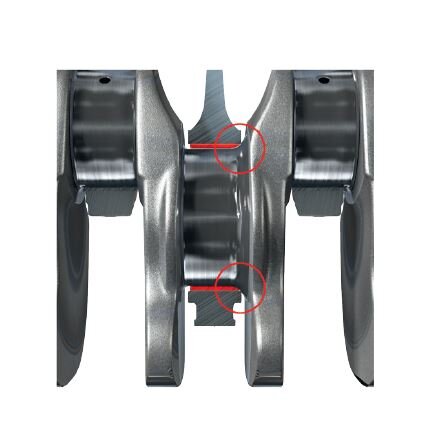

- Tapered ground journal (Fig. 1)

- Tapered bearing bore (Fig. 2)

- Rounding radius too large on one side (Fig. 3)

- Bending of the crankshaft: during installation, the crankshaft was not balanced or is deformed due to mechanical strain during operation

- Bearing bore which is not aligned due to bolts with the incorrect tightening torque during the assembly of the engine or excessive distortion of the main bearing centre line due to temperature development during operation

- Axial shell misalignment

Remedy

Bearings that exhibit edge wear can continue to be used depending on their wear condition. If these damage symptoms intensify after a few hours of operation, measures to determine the cause should be taken:

- Check for correct geometry of the crankshaft: dimensions, roundness, cylindricity, ripple, surface roughness

- Check the bearing line bore is correct: dimensions, roundness, cylindricity, surface

- Balance crankshaft during installation and check strain on the shaft

- Check alignment of the main bearing bore: during assembly of an engine, always make sure to use the specified tightening torques and bolt tightening sequence – the engine must be sufficiently cooled during operation as deformations may also occur due to temperatures that are too high

- Check connecting rods for angularity before installation