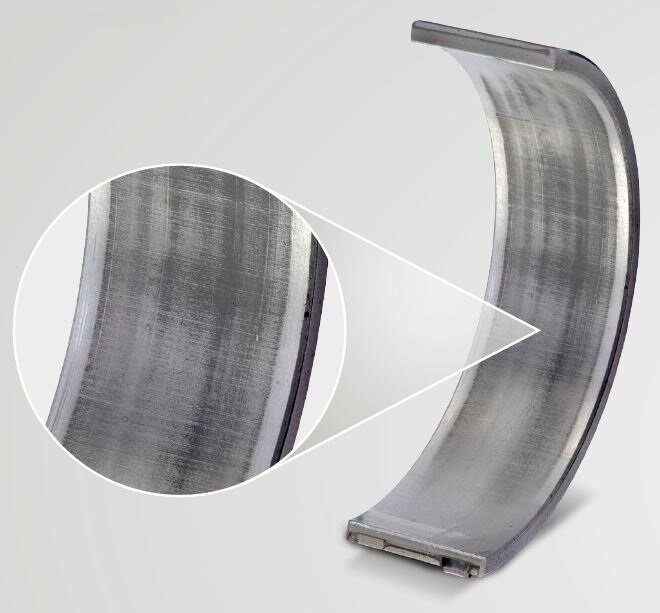

Narrow, wear-free strips at the edges of the bearings

DESCRIPTION OF THE DAMAGE

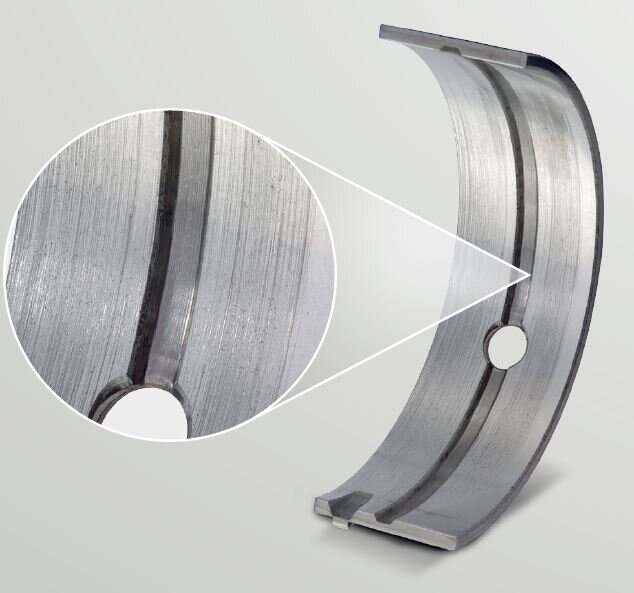

- Narrow, wear-free strips at the edges of the bearings

- No run-in marks visible in this area

- Machining structure from production still recognisable inthis area

- Clear definition between the wear-free strips and the worn area recognisable

Two wear-free strips are recognisable at the edges of the bearings without any visible wear marks. The remaining part of the bearing has a slight black discolouration, possibly due to corrosion or wear.

One wear-free strip is recognisable at the edges of the bearings without any visible wear marks. The remaining part of the bearing has pronounced scoring.

DAMAGE ASSESSMENT

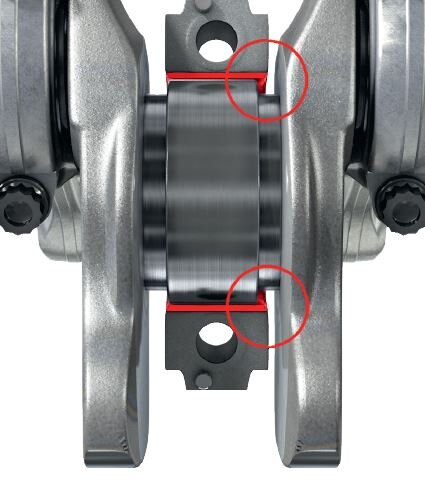

Due to one-sided (Fig. 1) or two-sided (Fig. 2)axial protrusion of the bearing shells, narrow, wear-free strips at the edges of the bearings are formed, which also do not demonstrate the typical adaptive run-in wear. Irrespective of the speed of the journal, there is never any metallic contact in these areas.

POSSIBLE CAUSES FOR THE DAMAGE

- Geometric deviations of the journal

- Incorrect choice of bearing width

- Clearance (shaft / journal misalignment)

Remedy

The bearings can continue to be used depending on their wear condition. They should be replaced as soon as initial rubbing marks develop or indicators of material fatigue become visible and measures to determine the cause should be taken:

- Check for correct geometry of the crankshaft before installation: dimensions, roundness

- Replace the crankshaft or install new bearings which fit the crankshaft geometry