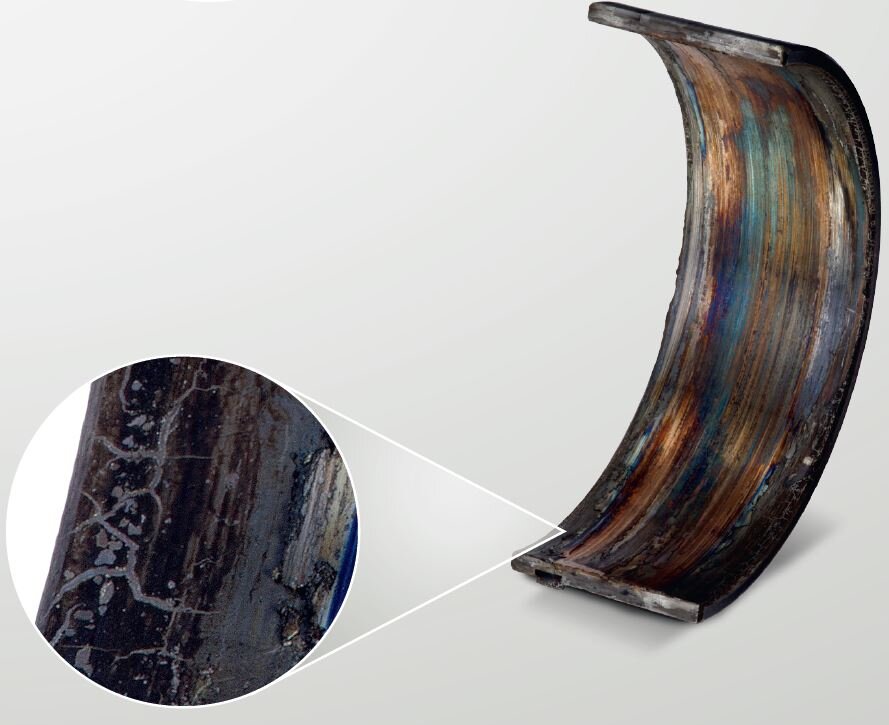

Heat cracks

DESCRIPTION OF THE DAMAGE

- A network of cracks is visible

- Fusing and discolouration of the bearing shell

Clear discolouration and fusion is visible on the sliding layer of the seized bearing shells. The crack formation is above all recognisable in the area of the edge.

Possible causes

- Consequential damage due to increasing temperature development as a result of initial rubbing marks, seizure or edge wear

- Insufficient heat dissipation provided by the lubricant

Remedy

If overheating damage occurs, the bearing must be replaced and the causes investigated. In the event of consequential damage, the cause of the primary damage must be rectified. If no further damage to the bearing is visible, the lubricant circuit and the stress on the bearing must be checked.