Cavitation

Cavitation is caused by the flow of the lubricant through the bearing gap. The vapour pressure of the oil used plays a crucial role here.

Seen correctly, cavitation is merely the physical process of the fuel vapour lock of a liquid, which in itself does not cause any damage to the bearing. The corresponding damage symptoms describe cavitation erosion through the material removal typical for this, as a result of the implosion of the vapour bubbles in areas below the vapour pressure (cavitation <–> cavitation erosion). Despite the different ways in which they are created, for some damage symptoms it can be difficult to differentiate between cavitation, erosion and corrosion. Often, complex transitional forms also appear such as cavitation erosion or erosion corrosion. This can be explained by the fact that both cavitation and erosion attack anti-corrosion layers, activate these chemically, resulting in corrosion.

Seen correctly, cavitation is merely the physical process of the fuel vapour lock of a liquid, which in itself does not cause any damage to the bearing. The corresponding damage symptoms describe cavitation erosion through the material removal typical for this, as a result of the implosion of the vapour bubbles in areas below the vapour pressure (cavitation <–> cavitation erosion). Despite the different ways in which they are created, for some damage symptoms it can be difficult to differentiate between cavitation, erosion and corrosion. Often, complex transitional forms also appear such as cavitation erosion or erosion corrosion. This can be explained by the fact that both cavitation and erosion attack anti-corrosion layers, activate these chemically, resulting in corrosion.

DESCRIPTION OF THE DAMAGE

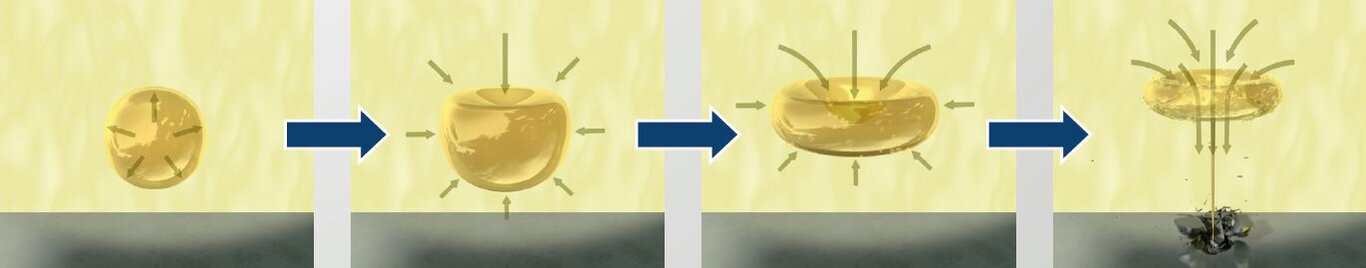

If the vapour pressure of the oil used is not reached, gas and vapour bubbles form which are transported further by the flow. This is known as cavitation. When the static pressure continues to increase, these bubbles collapse like an implosion, resulting in strong pressure surges – so-called microjets – as well as high temperatures. The pressure surges cause the material to break off and cause material removal, i.e. cavitation erosion.

Cavitation bubble is formed and grows -> Implosion begins -> Microjet is formed -> Microjet breaks through

the cavitation bubble and hits the surface

the cavitation bubble and hits the surface

- Cavitation in the relief: pointed or mushroom-shaped nick in the relief towards the parting face. The area is clearly roughened and matte

- Cavitation in the run-out of the oil groove: mushroomshaped nick in the run-out of the oil groove, roughened and matte area

Cavitation may also occur in other areas of the bearing, such as in the crown. These forms are, however, much harder to differentiate from erosion and corrosion. Generally, you do not find material nicks such as with the forms mentioned above, but instead matte, slightly roughened areas which could also be theresult of erosion or corrosion.

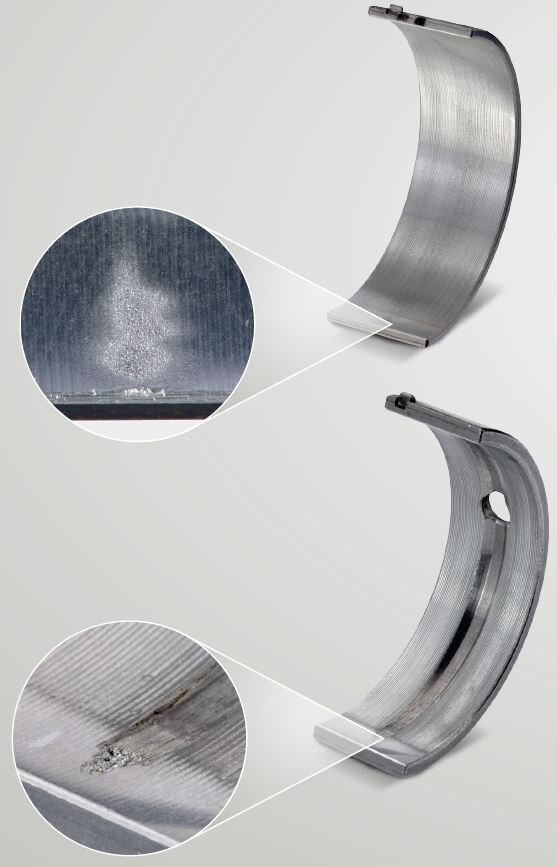

Cap-side conrod bearing shell steel-aluminium composite

Cavitation in the relief: material removal can clearly be seen – the area is matte compared to the surrounding material.

Upper main bearing shells steel-aluminium composite

Cavitation in the run-out of the oil groove: a mushroom-shaped nick in the bearing material can be seen. The area is much more matte and roughened compared to the surrounding material.

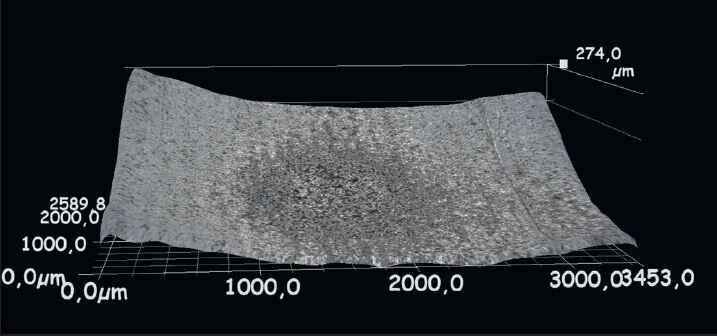

Cavitation in the relief: material removal can clearly be seen – the area is matte compared to the surrounding material.

Upper main bearing shells steel-aluminium composite

Cavitation in the run-out of the oil groove: a mushroom-shaped nick in the bearing material can be seen. The area is much more matte and roughened compared to the surrounding material.

DAMAGE ASSESSMENT

Pressure surges caused by the implosion of gas and vapour bubbles near to the surface of the bearing result in material nicks. Cavitation often comes hand-in-hand with erosion and corrosion and can cause fine scoring in the same or adjacent bearings.

Possible causes

High temperatures and low-boiling impurities may advance cavitation.

Vibration or suction cavitation:

Flow cavitation:

Breaks in the surface (oil bores, oil grooves) and diversion of the oil flow may cause a reduction in pressure

- Impurities in the oil: water, fuel or deposits from abrasion and dirt

- Oil pressure that is too low: unforeseen loss of pressure (for example due to defective oil pump) is present or the oil pressure is set too low

- The vapour pressure of the oil used is too low

- Increase in temperature in the bearing (for example due to a lack of oil)

- Oils with low viscosity increase the risk of cavitation

- Hollow areas / foreign particles (for example carbon deposits) at the back of the bearing may cause vibration of the bearing shell, resulting in cavitation

Vibration or suction cavitation:

- Lubrication gap is too large, causing the hydrodynamic pressure in the bearing gap to fall

- Crankshaft vibration: journal movement causes a reduction in pressure on one side due to resulting suction effect

- Vibration in the bearing bore (generally for connecting rod eyes) due to deformation or bending – resulting in a reduction in pressure in the oil film

Flow cavitation:

Breaks in the surface (oil bores, oil grooves) and diversion of the oil flow may cause a reduction in pressure

Remedy

Bearings which demonstrate cavitation do not need to be replaced. Depending on the extent of the cavitation, the service life may be reduced due to the influence on the dynamics of the bearing. Complete failure is not a concern, however.

- Use quality oils and replace the oil and filter regularly in accordance with the manufacturer‘s specifications

- Check the oil pressure and readjust if necessary

- Use an oil with a higher vapour pressure: the oil must be compatible with all engine components, however. Consult the manufacturer for advice if necessary

- Check the lubricating gap and readjust bearing clearance if necessary

- Check the engine for vibration stress

- Check the oil for fuel dilution