Damage to thrust washers

Thrust washers enable the absorption of axial forces, which arise when the clutch is actuated, for example. This means one bearing position is always axially supported in the main bearing set. This is realised through the use of thrust washers or pre-assembled, ready-for-installation collar bearings or flanged bearing halves.

Possible causes

- Axial clearance too low, meaning that the thrust washer is pressed against the interacting sliding parts

- Axial stress too high

- Sustained axial stress

- Shaft flange too rough

Remedy

- Check the axial clearance of the crankshaft and keep to the specified tolerance range – if necessary use a thrust washer with undersize grade

- Check the axial stress on the thrust washer

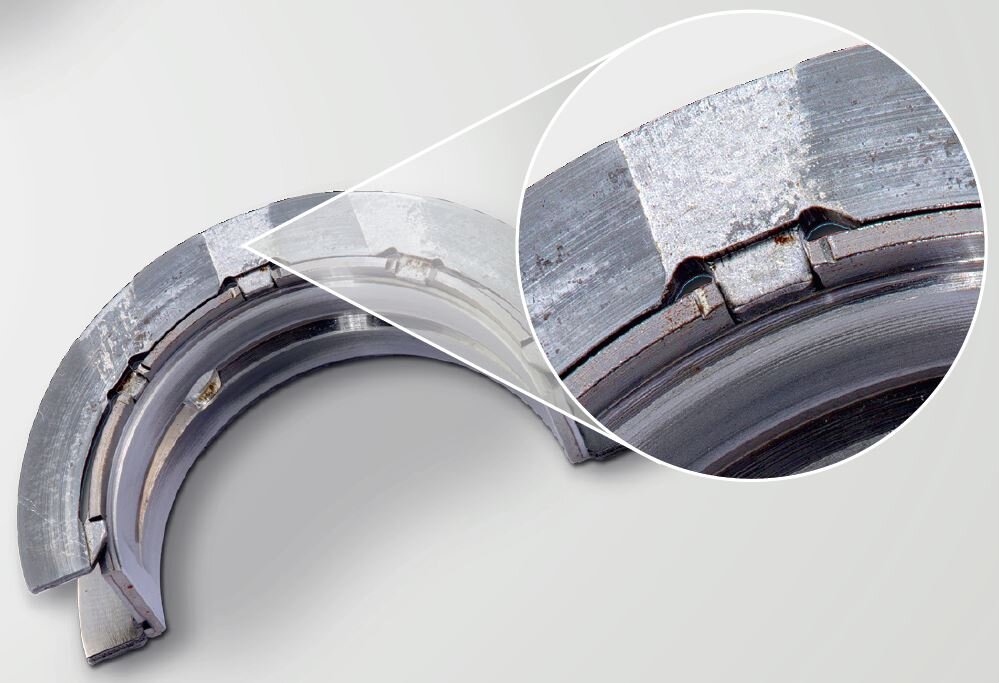

Sliding wear

Wear marks are visible on the sliding surface of the thrust washer

Wear marks are visible on the sliding surface of the thrust washer

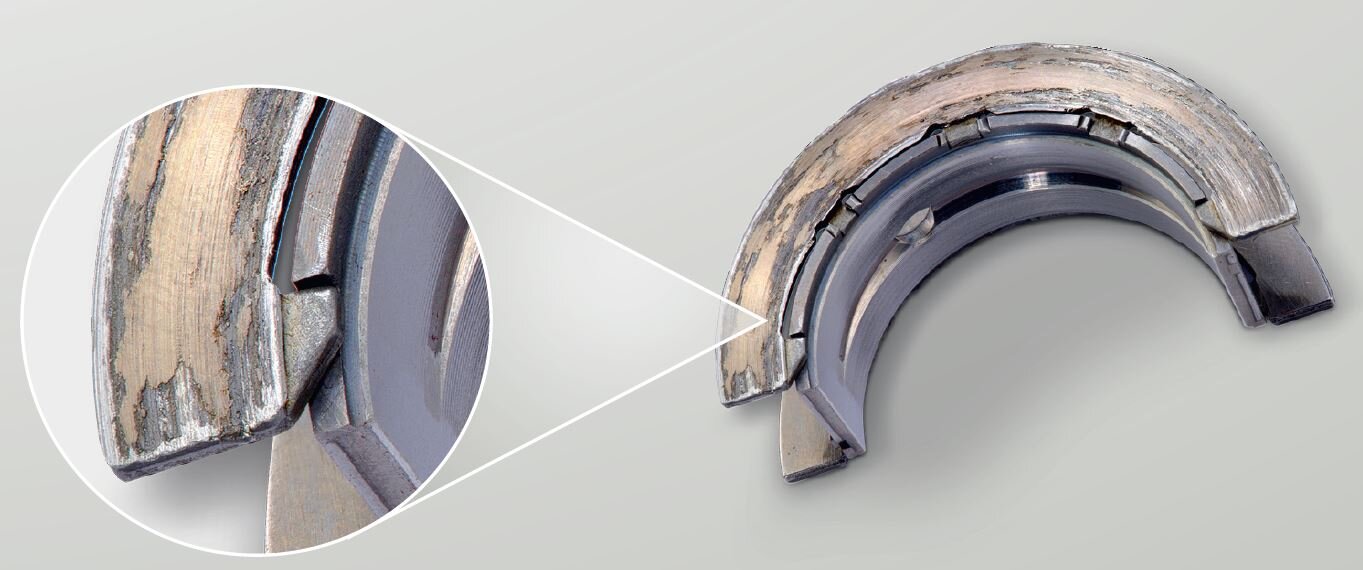

Advanced sliding wear

Material displacement and removal; oil groove hardly still there

Material displacement and removal; oil groove hardly still there

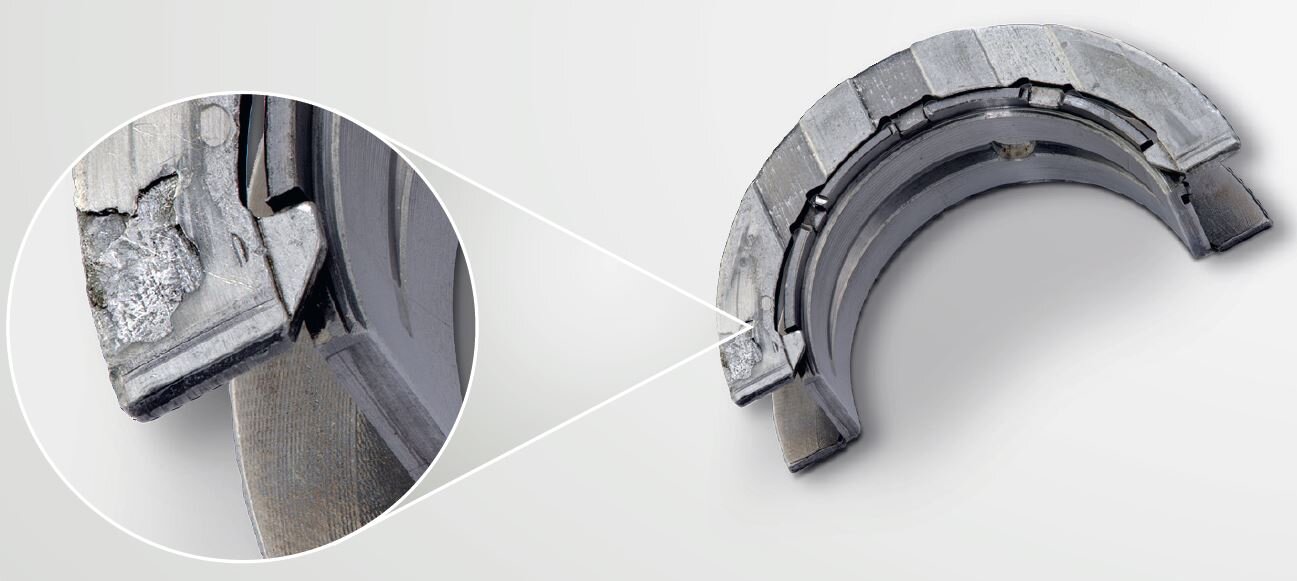

Seizure

Areas of torn-out material and pronounced scoring; oil grooves are no longer visible

Areas of torn-out material and pronounced scoring; oil grooves are no longer visible