Scoring

DESCRIPTION OF THE DAMAGE

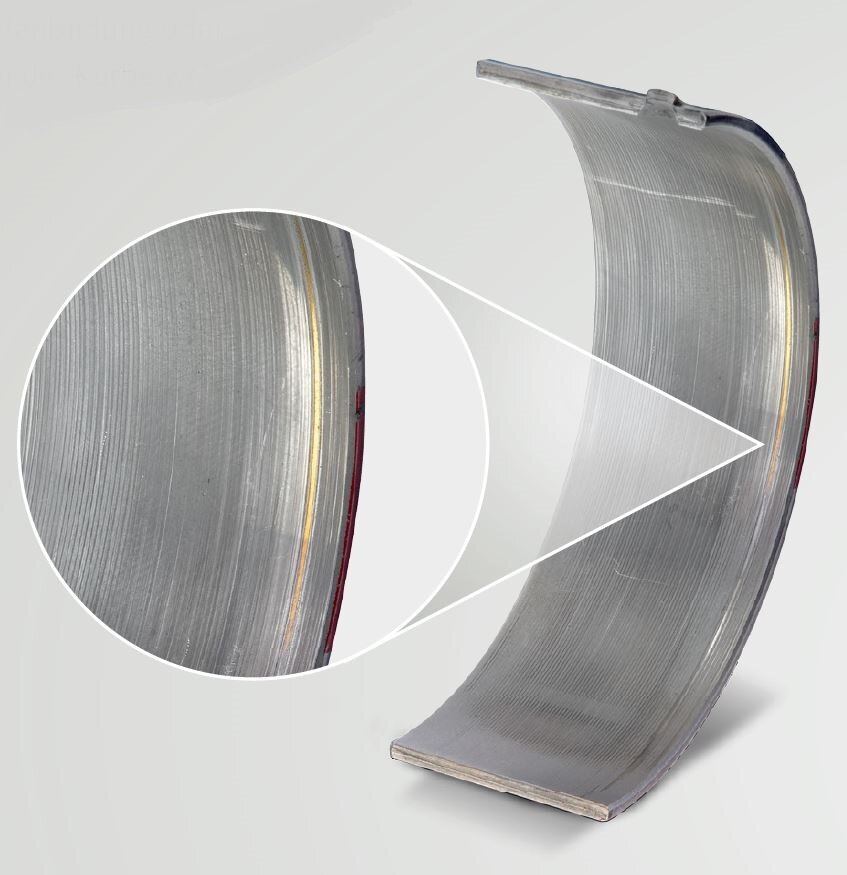

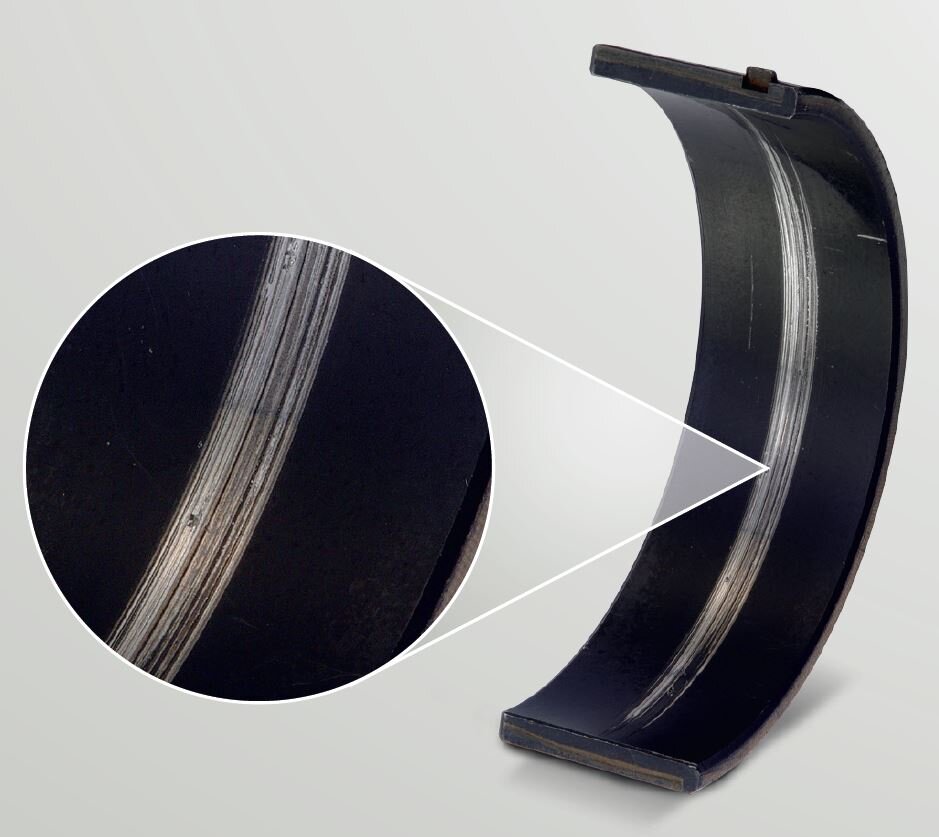

- Stroke-like recesses in the sliding direction with material accumulation at the edges

- The areas of material accumulation are partially levelled out again due to wear, bright and light

- Generally in line with scoring or embedded particles in the crankshaft or adjacent bearings

The groove extends up to the brass layer. Light wear marks occur next to the scoring due to smoothed material accumulation.

The grooves are worn up to the aluminium alloy layer.

DAMAGE ASSESSMENT

Particles which find their way into the lubricant gap and are not embedded into the bearing material are repeatedly forced through the gap, causing grooves in the process. Depending on the thickness of the edges created, these cannot be flattened during further operation and, due to increased mixed friction, there is an increase in temperature in the event of shaft contact.

This often leads to initial rubbing marks and seizure. The scoring may also be the result of the influence of mixed friction. Here, the grooves are fine and formed on the surface,however, and appear at both interacting sliding parts.

This often leads to initial rubbing marks and seizure. The scoring may also be the result of the influence of mixed friction. Here, the grooves are fine and formed on the surface,however, and appear at both interacting sliding parts.

Remedy

If grooves with pronounced material accumulation are present atthe edges, the bearing must be replaced. If grooves are present with areas of material accumulation which have been flattened, and no further influence of particles can be expected, the bearings can still be used.