Embedding

DESCRIPTION OF THE DAMAGE

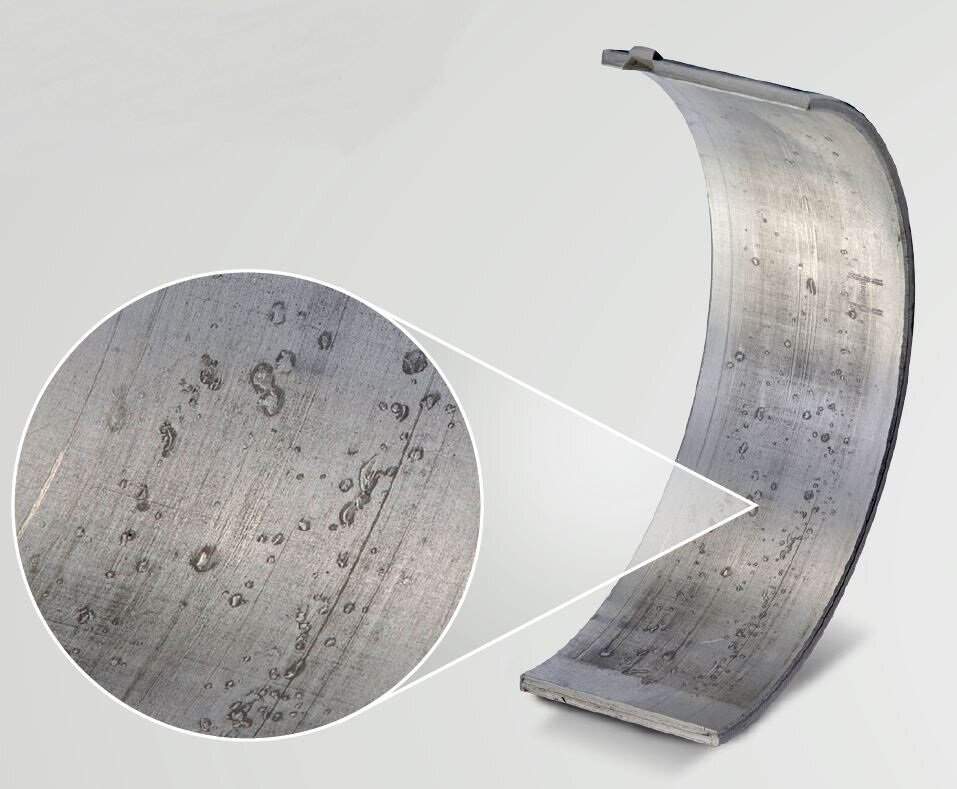

- Scarred surface

- Particle imprints (still containing particles in places),surrounded by material accumulation which is visible as a light shining point due to wear

- Often in conjunction with scoring in the journal and bearing

- In severe cases, initial rubbing marks from the embedding are visible

Fine particle imprints and individual scoring marks are visible.

Large particle imprints without embedded particles are visible. The particles have caused areas of material accumulation which have caused an initial rubbing mark in the centre of the bearing.

DAMAGE ASSESSMENT

Particles which find their way into the lubricant gap may become embedded in the bearing material. Depending on the thickness of the sliding layer, we can differentiate between deep and shallow embedding. In the case of deep embedding, the particles are completely integrated into the sliding layer. This is only possible when the particle is smaller than the thickness of the layer. The material accumulation created during the embedding is flattened during the subsequent contact with the shaft due to wear. Shallow embedding takes place when the size of the particle is greater than the thickness of the layer. The particles are not completely embedded and protrude from the bearing surface. They cause wear and scoring on the journal surface. Due to the material accumulations at the edges or protrusions from particles which are not completely embedded, the formation of the lubricant film is disrupted, and mixed friction conditions may be created. So-called „wire-wool“ wear is a possible consequence. Here the embedded particles cut into the surface of the shaft and remove material (chipping wool). The particles that break away, which are then embedded again, accelerate the bearing damage, and often complete failure of the journal and bearing cannot be avoided.

Initial rubbing marks and seizure can therefore result from particle embedding.

Initial rubbing marks and seizure can therefore result from particle embedding.

Remedy

If large particle embedding in conjunction with initial wear of the journal and bearing is present, the bearing must be replaced. If fine particle embedding is present, the material accumulation of which has been flattened and no further influence of particles can be expected, the function of the bearing is not impaired.