Chemical corrosion

DESCRIPTION OF THE DAMAGE

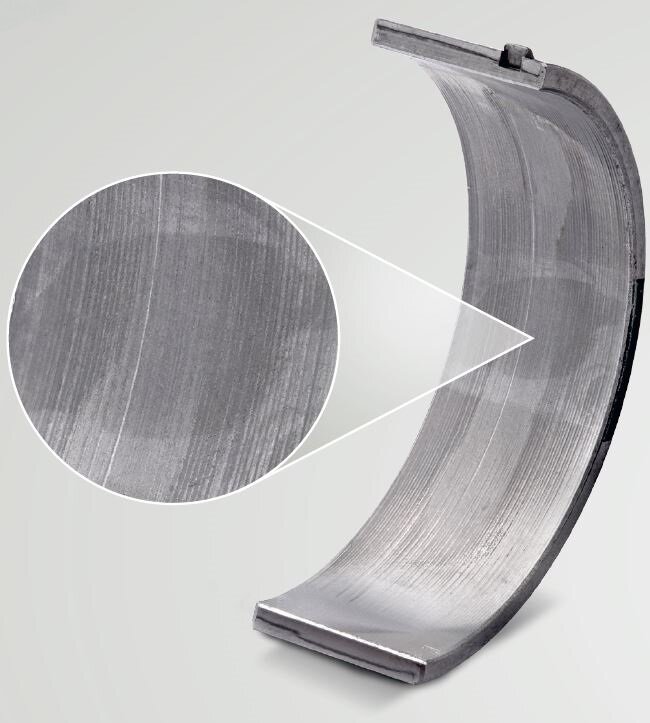

- Discolouration of the material surface, mainly in the main load area

- Sliding surface rough and porous

Deposits from corrosion products are visible in the bearing sliding surface, especially pronounced in the centre of the bearing. The deposits appear in the formation of stains. When studied under a microscope, roughening of the bearing sliding surface can be seen in the corroded area.

Damage assessment

Chemical corrosion is caused by reactions between the bearing shell and engine oil. Triggers for the chemical reaction are aggressive additives in the oil or oil contamination during operation.

The integrity of the material is adversely affected by the chemical attack, meaning that fatigue damage is accelerated, even with low stress.

The integrity of the material is adversely affected by the chemical attack, meaning that fatigue damage is accelerated, even with low stress.

Possible causes

- Wear, cavitation and erosion can assist corrosion since they attack the material surface and activate it chemically

- Formation of acids and metal salts as a result of oil ageing

- Impermissible, aggressive oil additives

- Aggressive products from combustion (sulphur, hydrogen sulphide)

- Contamination of the oil with water or antifreeze

- High operating temperatures accelerate chemical processes such as oil ageing

Remedy

Corroded bearings must be replaced.

- Always carry out oil changes in accordance with the manufacturer‘s instructions

- Only use quality oils free from aggressive additives

- Cool engine sufficiently