Torn-off flange on the cylinder liner

DESCRIPTION OF THE DAMAGE

- Liner flange has been torn off.

- The flange crack starts at the base of the bottom edge of the liner flange and extends upwards at an angle of approx. 30°.

DAMAGE ASSESSMENT

This type of damage is caused by bending moments that arise as a result of improper installation (dirt/form defects). In most cases, the cylinder liner flange is already pressed off when the cylinder head is tightened down. On the latest generations of engines for commercial vehicles with pump-nozzle unit or common rail fuel injection systems, the engine block is subjected to increasing loads as a result of the increasing combustion pressures. The use of very hard steel cylinder head gaskets on these engine types can cause distortion of the crankcase in the area of the liner flange seating surface after the engine has been in operation for a long time.

|

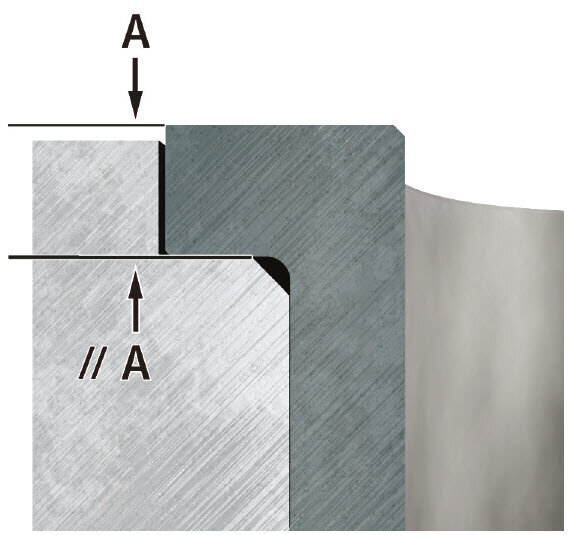

NOTE The distortion of the seating surface cannot be detected by visual inspection alone unless the appropriate measuring aids are used. One simple way to check for this distortion is the use of bearing ink: thinly apply the ink around the seating surface of the liner flange on the engine block. Then insert the new liner without gaskets and press it onto the seat. Remove the cylinder liner again. The seating surface on the cylinder liner should now be evenly coated with ink around the entire circumference. If this is not the case, the liner seat needs to be reworked. This reworking is best performed on a stationary boring machine or with a mobile liner flange seat facing attachment. This ensures parallelism with respect to the housing surface (Fig. 2). |

POSSIBLE CAUSES FOR THE DAMAGE

- Worn liner flange seating surfaces on the engine after an extended running period.

- Dirty or corroded liner flange seating surfaces.

- Failure to ensure that the flange seat is perfectly rectangular and/or parallel (Fig. 2 and Fig. 5).

- Incorrect cylinder head gaskets.

- Non-compliance with the engine manufacturer‘s prescribed tightening torques and tightening angles when installing the cylinder head.

- Wrong number of sealing rings.

- Sealing rings jammed underneath the liner flange.

- Use of incorrectly dimensioned gaskets.

- Use of liquid sealants.

- In the case of dry press fit cylinder liners: installation fault through excessively high press-in force.

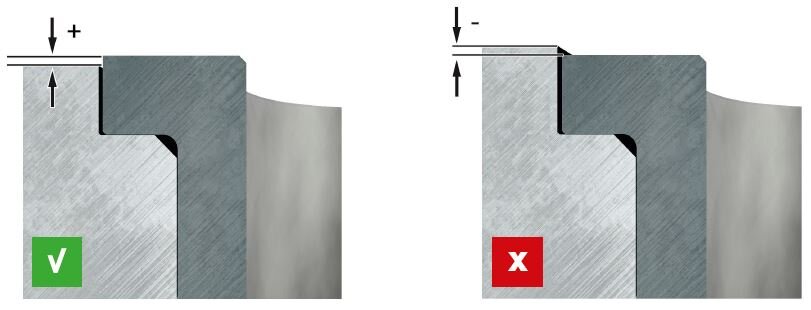

- Prescribed liner protrusion not complied with (Fig. 6):

- If the protrusion of the cylinder liner is too great, then the liner flange is pressed off when the cylinder head bolts are tightened.

- If the protrusion is too small, the cylinder liner is not pressed onto the liner seat with enough force and adopts a pendulum motion as a result of the piston movement. These forces cause the liner flange to be torn off.

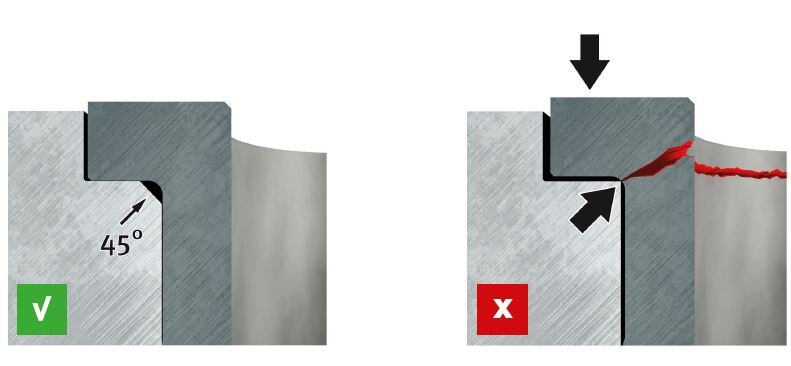

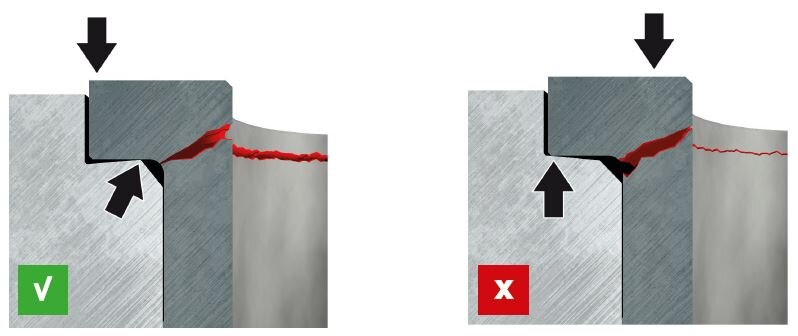

- Reworking of the liner seat without due care for the proper form. The form of the liner seat must correspond to the form of the cylinder liner. The transition from the flange surface to the precision-fit seat diameter must have a chamfer of 0.5–1.0 mm х 45° to prevent the fillet on the liner flange from making contact with the edge. If this is not ensured then it is very easy for the liner flange to be pressed off when the cylinder head is tightened down (Fig. 3). Furthermore, the rounding radius of the liner seat (“D” in Fig. 4) must not be so large that it prevents the cylinder liner from bearing loads at the inner or outer edge on the liner flange.

|

NOTE When reworking the liner flange seating surface during engine reconditioning, the necessary protrusion of the cylinder liner over the cylinder surface must be ensured, either by inserting steel washers underneath or by using a cylinder liner with an oversized flange* (recommended). |