Cavitation on cylinder liners

DESCRIPTION OF THE DAMAGE

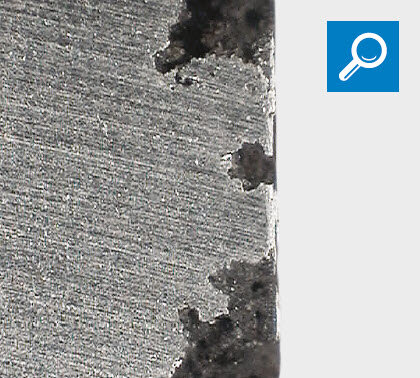

- Severe cavitation on the water jacket of the wet cylinder liner (Fig. 1 and 2).

- Coolant has penetrated through into the combustion chamber.

DAMAGE ASSESSMENT

Cavitation is more likely to occur in the tilting plane of the piston (on the pressure or anti-thrust side) and is triggered by high-frequency vibrations of the cylinder wall. These vibrations are caused by the lateral forces exerted by the pistons, the combustion pressure and the change of bearing surfaces at TDC and BDC. If the coolant is no longer capable of following the vibrations of the cylinder wall, this results in the water film separating from the cylinder liner. Vapour bubbles form in the resulting area of low pressure, and when the cylinder wall vibrates back at exceptionally high speed, these bubbles implode. The water displaced by the bubbles hits the surface of the cylinder very suddenly. The impact energy generated in this way dissolves tiny particles. With time, complete holes are torn out (washed out).

A special feature of cavitation is the fact that the size of the holes increases further inside the material (Fig. 3), resulting in the cavities in the material.

Causes of cavitation

A special feature of cavitation is the fact that the size of the holes increases further inside the material (Fig. 3), resulting in the cavities in the material.

Causes of cavitation

- Coolant temperature too high.

- Coolant pressure too low.

- Coolant boiling point too low.

- Combination of the above.

POSSIBLE CAUSES FOR THE DAMAGE

- Failure to comply with the correct piston clearance, e.g. re-installation of pistons that have already been used, or use of cylinders manufactured too large.

- Irregularity in liner flange seating surface – poor or inaccurate seating of the cylinder liner in the housing (refer to the chapter entitled “Torn-off flange on the cylinder liner”).

- The required permanent anti-freeze protection with corrosion protection or corresponding additives in the coolant are missing. The anti-corrosion agent contains inhibitors that prevent foaming. However, these inhibitors are used up with time. Therefore it is necessary to change the anti-corrosion agent every 2 years and to use the correct mixture ratio.

- Unsuitable coolants such as salt water (sea water), aggressive or acidic water or other liquids.

- Insufficient pre-pressure in the cooling system. Reason: unsuitable radiator cap (not enough pressure can be maintained due to a defective pressure relief valve) or because of a leak in the cooling system. If the pre-pressure in the cooling system is in accordance with the requirements, the boiling point of the coolant is higher than under atmospheric pressure. Although the pre-pressure does not eliminate the cause of the formation of the vapour bubbles, it can at least inhibit the formation of the bubbles.

- Incorrect sealing rings and/or sealing compound or silicone on the liner flange.

- Incorrect number of sealing rings.

- Engine operating temperature too low: if the engine does not reach its normal operating temperature due to particular operating conditions or thermostat defects, no overpressure can build up in the cooling system because of the reduced thermal expansion of the coolant. The low operating temperature also means that the pistons do not expand in the required manner. As a result they run with inwcreased piston clearance. Both cases assist the formation of the bubbles and hence the cavitation.

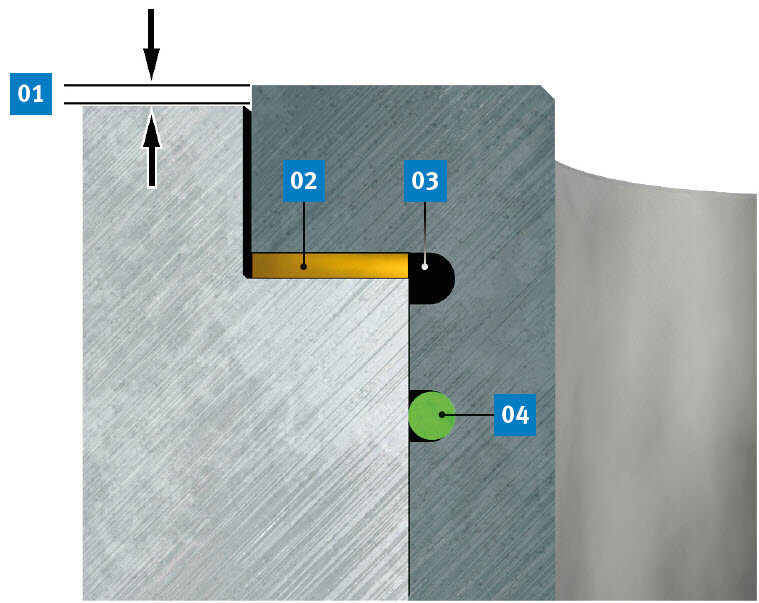

- Installation of additional sealing rings in the undercut on the liner flange (Fig. 4): sealing rings may only be installed at this position if they are specifically required by the manufacturer.

- Liner protrusion

- Tombak shim

- Undercut

- O-ring