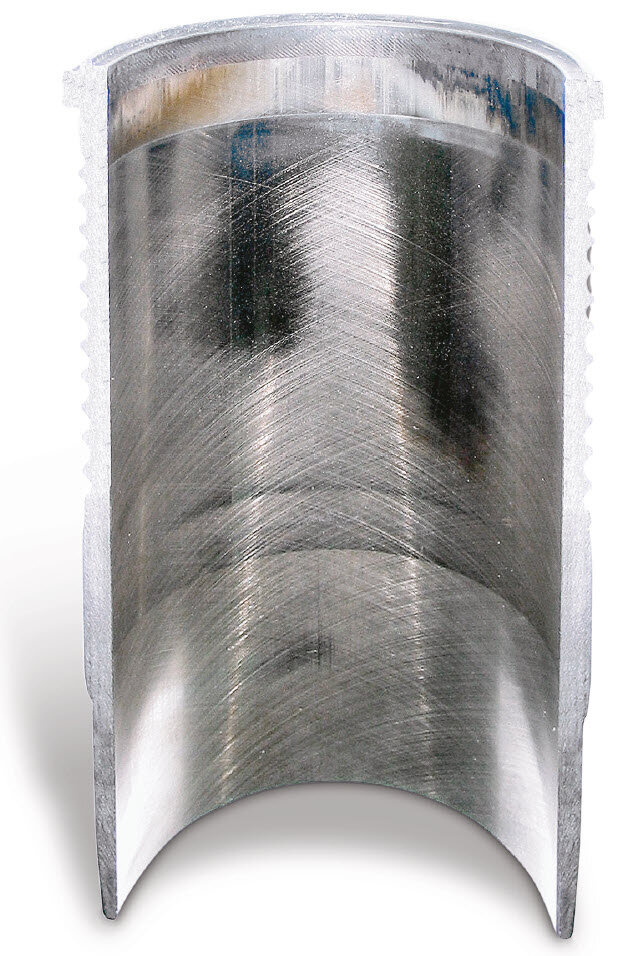

Bright spots in upper sliding surface area

DESCRIPTION OF THE DAMAGE

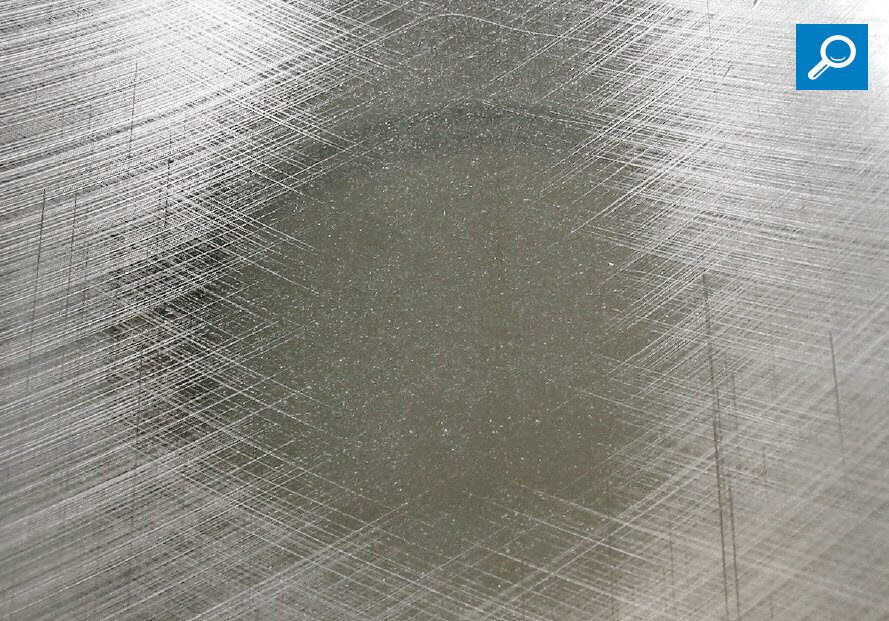

- Bright, bare areas with no honing structure on cylinder sliding surface (Fig. 1 and 2).

- No signs of wear on the piston.

- Oil carbon deposits on the piston top land.

- Increased oil consumption.

DAMAGE ASSESSMENT

This type of damage pattern occurs when a hard oil carbon coating forms in operation on the piston top land as a result of burned oil and combustion residue (Fig. 3). This coating has abrasive properties, which lead to increased wear in the upper part of the cylinder in operation due to the reciprocal motion and the change of bearing surfaces of the piston. The increased oil consumption is not caused by the bright spots themselves, as the polished areas do not cause noticeable out-of-roundness of the cylinder, and the piston rings can still continue to perform their sealing duties. The lubrication of the cylinder is also unaffected, as it is still possible to retain enough oil in the open graphite veins of the cylinder surface despite the loss of the honing structure. When assessing this type of damage, it is important to note that, in this case, the bright spots all coincide with points in the cylinder that come into contact with the carbonised piston top land. If the bright spots are also present at other points, then the cause for the damage is more likely to be found:

- in distortion of the cylinder (refer to the chapter entitled “Irregular sliding surface wear”),

- fuel flooding (refer to the chapter entitled “Wear on pistons, piston rings and cylinders caused by fuel flooding”),

- or ingress of dirt or contaminants (refer to the chapter entitled “Wear on pistons, piston rings and cylinder running surfaces caused by the ingress of dirt”).

POSSIBLE CAUSES FOR THE DAMAGE

- Excessively high ingress of engine oil into the combustion chamber due to a defective turbocharger, inadequate oil separation in the engine ventilation system, defective valve stem seals, etc.

- Overpressure in the crankcase due to increased emissions of blow-by gases or due to a defective crankcase ventilation valve.

- Inadequate cylinder finishing, resulting in increased ingress of oil into the combustion chamber (refer to the chapter entitled “Piston ring wear soon after engine reconditioning”).

- Use of non-approved engine oils or engine oils of a lower quality.