Swirl chamber inserts

The correct handling of older cylinder heads

Information on use

What are swirl chamber inserts? How high is the swirl chamber projection? What problems may occur in cylinder heads with swirl chambers? Can you rework cylinder heads with swirl chamber inserts on the sealing areas? And can swirl chamber inserts cause mechanical noises in the engine? You can find answers to these and many other questions here.

SITUATION

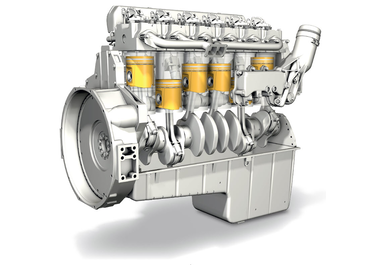

Diesel engines with indirect injection are still frequently in use today. Engines that function using the swirl chamber principle are still common.

INSTALLATION SITUATION

Cylinder head problems in swirl chamber engines mostly arise in the form of engine overheating, as a result of incorrect cylinder head repair or handling. Some frequently asked questions are answered below.

FAQS

QUESTION: WHEN I DISMANTLE THE CYLINDER HEAD, SOME SWIRL CHAMBER INSERTS JUST FELL OUT. CAN I GET THE HEAD REPLACED UNDER WARRANTY?

Answer: This is not a reason for complaint. If the inserts fall out of their own accord while the cylinder head is being dismantled, this indicates that there may have been irregularities in combustion (overheating) while the engine was in operation. Inserts expand to a greater extent when overheated than during normal operation. This causes the bore in the cylinder head to widen slightly. When it cools down, some clearance opens up between the cylinder head and the swirl chamber insert, and the insert falls out. As long as the location hole for the swirl chamber insert is undamaged and the insert has the projection specified by the manufacturer, the cylinder head can be reused. To prevent the inserts from falling out during the removal of the cylinder head, they can be fixed in the cylinder head with a little grease.

QUESTION: CAN LOOSE SWIRL CHAMBER INSERTS LEAD TO A LOSS OF COOLANT?

Answer: No! The swirl chambers are not connected to the coolant. The loss of coolant in the cylinder head is always a result of engine overheating (abnormal combustion). This leads to cylinder head distortions, to faulty cylinder head gaskets and the formation of cracks. In this case, loose swirl chamber inserts are only a symptom of the real problem.

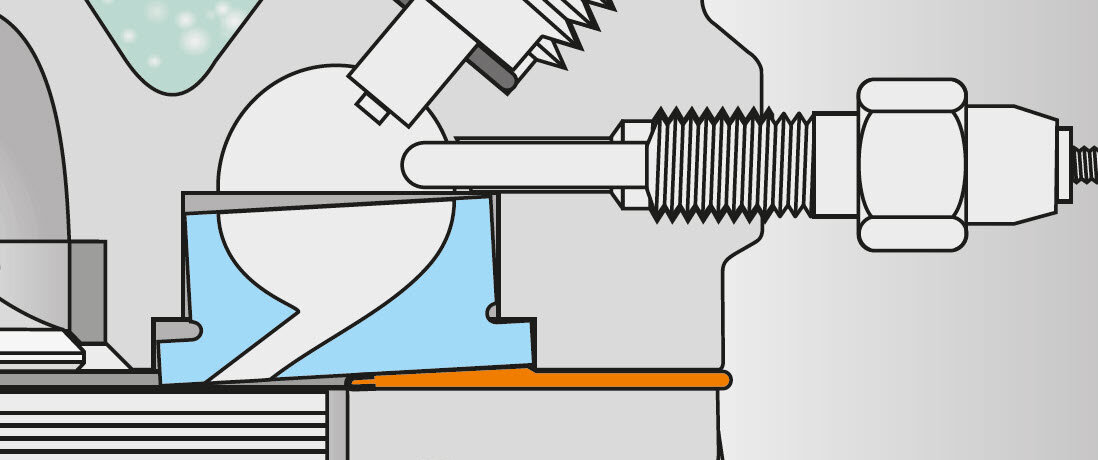

QUESTION: HOW DOES THE SWIRL CHAMBER CAUSE GAS TO LEAK FROM THE CYLINDER HEAD GASKET?

Answer: There are two different causes for this. 1. The swirl chamber did not have the necessary projection in relation to the face of the cylinder head on installation. 2. Engine overheating has caused the swirl chamber to set in the cylinder head. In both cases, the loss in the projection of the swirl chambers results in a loss in the surface pressure of the cylinder head gasket in this area. Leaks are the unavoidable consequence.

QUESTION: CAN THE SEALING FACE OF CYLINDER HEADS THAT ARE EQUIPPED WITH SWIRL CHAMBER INSERTS BE REGROUND?

Answer: Although many engine manufacturers do not approve the regrinding of the cylinder head face, it is certainly possible and also frequently carried out in practice.

|

ATTENTION Never regrind the cylinder head face with the swirl chamber inserts installed. Before regrinding the face, removal of the swirl chamber inserts is essential. Then, when reinstalling the inserts, you must check that the swirl chambers have the necessary projection, and take suitable measures (remachining the swirl chamber seat or grinding the swirl chamber insert) to adjust this if necessary. |

|

NOTE Cylinder heads warped due to overheating must not be reground. They must be scrapped. |

QUESTION: IN WHAT CASES CAN SWIRL CHAMBER INSERTS CAUSE MECHANICAL ENGINE NOISE?

Answer: This can have different causes. 1. The swirl chamber has set, or did not have the necessary projection on installation. The swirl chamber insert tilts in its seat and collides with the piston. This tilting is compounded by the combustion pressure and overheating of the chamber (poor heat dissipation, Fig. 3). 2. If the engine overheats, e.g. due to abnormal combustion, the components expand considerably. This cancels out the free movement of the piston, so that it knocks against the swirl chamber, the valves and the cylinder head. Impact marks from the swirl chamber insert (arrow) and intake valve can be seen on the piston in Figure 4. The damage was caused by engine overheating. 3. Attention was not paid to ensuring the correct piston protrusion during installation of the cylinder head, and a cylinder head gasket with the incorrect thickness was installed. This causes the piston to knock against the swirl chamber insert during operation.