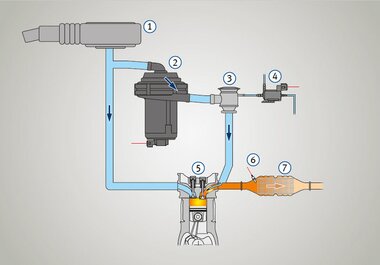

Secondary-air system (2)

trouble-shooting

Information on diagnostics

Are you hearing a scratching or whistling noise in the engine compartment during cold starts? Is the fault code memory showing diagnostic trouble code P0410 or P0411?

We explain the causes of this noise and how to check the secondary air pump and secondary air valve.

Secondary-air system and OBD

European EOBD only checks the electrical connection of the secondary-air system, but not its action.

The electrical connection is monitored for short to earth, short to power supply and open circuit.

The American on-board diagnosis version OBD II monitors the action of the secondary-air system:

As a check, the secondary-air pump is switched on once per driving cycle with the engine warm.

The Lambda sensor thus registers excess oxygen. The probe signal is compared to the set values in the control unit.

Possible OBD fault codes:

- P0410 Malfunction

- P0411 Insufficient quantity

An open secondary-air valve can lead to biasing of the Lambda probe signal as being “too lean”. This may result in the following fault message:

- Lambda sensor – Control limit reached

Trouble-shooting advice

The most common problems relating to secondary-air systems are:

- Noisy secondary-air pump

- No secondary-air pump operation

In most of these cases, a defective nonreturn valve or incorrect actuation of the secondary-air valve has led to exhaust gas condensate ingressing into and damaging the secondary-air pump.

The standard remedy is then just to replace the secondary-air pump, which often leads to the same problem occurring again in a short space of time.

The malfunctioning of just one component in the secondary-air system can result in damage to other components. If problems arise it is therefore essential to check all the components.

Checking: Secondary-air pump

With a cold engine, the secondary-air pump must be heard to start up for max. 90 seconds after starting.

For component checking with a warm engine, the secondary-air pump connector can be unplugged and supplied with vehicle electrical system voltage.

The secondary-air pump is not designed for continuous operation, i.e. it should not be allowed to run for more than 90 seconds.

- The secondary-air pump must be replaced if it does not run or makes a scraping, whistling or scratching noise during operation.

- In such cases, the other secondary-air system components should also be checked.

- Check for contamination of the engine air filter.

If the secondary-air is drawn in directly from the engine compartment rather than from the intake system, the separate air filter fitted upstream of the secondary-air pump may be clogged.

Checking: Secondary-air valve

- The secondary-air valve must be replaced if it does not open on applying vacuum.

- If the secondary-air valve opens on applying vacuum, the solenoid actuation valve (solenoid switching valve) and the vacuum hoses must be checked.

- The secondary-air valve diaphragm is leaking if the vacuum applied with the vacuum hand pump decreases.

- Deposits on the side facing the secondary-air pump (check with finger, refer to adjacent illustration) are an indication of non-return valve leakage.

- To check, unfasten the connecting hose between the secondary-air pump and secondary-air valve.

Checking: Solenoid switching valve

- The solenoid switching valve is energised for the duration of secondary-air injection (cold starting phase). The solenoid switching valve is open when energised and closed when deenergised.

- A vacuum hand pump can be used to check for opening and leakage.

- During secondary-air injection, electrical system voltage must be applied to the connector of the solenoid switching valve. If not, an electrical fault has occurred which must be localised with the help of a circuit diagram.

Checking: Vacuum system

- The control vacuum may not be attained in the event of leakage.

- A manometer, e.g. on the vacuum hand pump, can be used to check the control vacuum at the solenoid switching valve and on vacuum-controlled secondary-air valves.

- If a minimum control vacuum of 390 mbar (corresponding to an absolute pressure of 610 mbar) is not attained, the entire vacuum system must be examined for leaks and the damaged component replaced.

Possible sources of trouble:

- Defective hoses (porous, rodent attack)

- Leaking connections at pneumatic valves

- Leaking non-return valves/vacuum accumulator

- Defective/porous diaphragms or seals at pneumatic actuators

- Leakage in intake manifold

- Defective vacuum pump

Checking: Connection to exhaust manifold

Exhaust gas may be heard to escape at the connecting flange if a seal is defective.

- Check the connection for leaks and re-seal if necessary.