Pressure oil filling on reconditioned engines

Information on use

How do we fill the engines with oil after reconditioning? Why pressure oil filling? How can running-in damage be avoided on reconditioned engines? What must be taken into account before starting new and reconditioned engines? You can find a detailed description here.

SITUATION

After an engine has been completely overhauled, the plain bearings may be damaged immediately during initial startup. The reason: Oil pressure can only be built up by the oil pump once the oil pressure system is filled with oil and vented. If the engine is started in dry state, it may take too long for the oil to reach the bearing positions. The highly stressed plain bearings of the connecting rods in particular suffer from the inadequate oil supply. During the first start phase, the connecting rod bearings are mainly lubricated with the oil applied during mounting. These emergency reserves are used up too quickly, however, and the bearing positions are damaged due to mixed friction and overheating.

REMEDY

To prevent damage during the initial start-up, it is advisable to fill the oil pressure system manually with engine oil before starting up the engine. This ensures that any air is removed from the oil pressure system and ensures that the components work safely from the start. In addition to the plain bearing positions, hydraulic chain tensioners, hydraulic camshaft adjustment, hydraulic tappets and engine components lubricated with engine oil, like turbochargers, fuel feed pumps, fuel injection pumps and vacuum pumps, also benefit from this process.

|

NOTE This procedure is generally specified by many renowned engine manufacturers for the initial start-up of new or reconditioned engines. |

NEXT STEPS

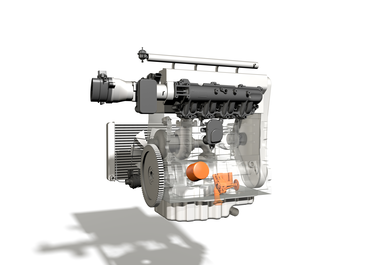

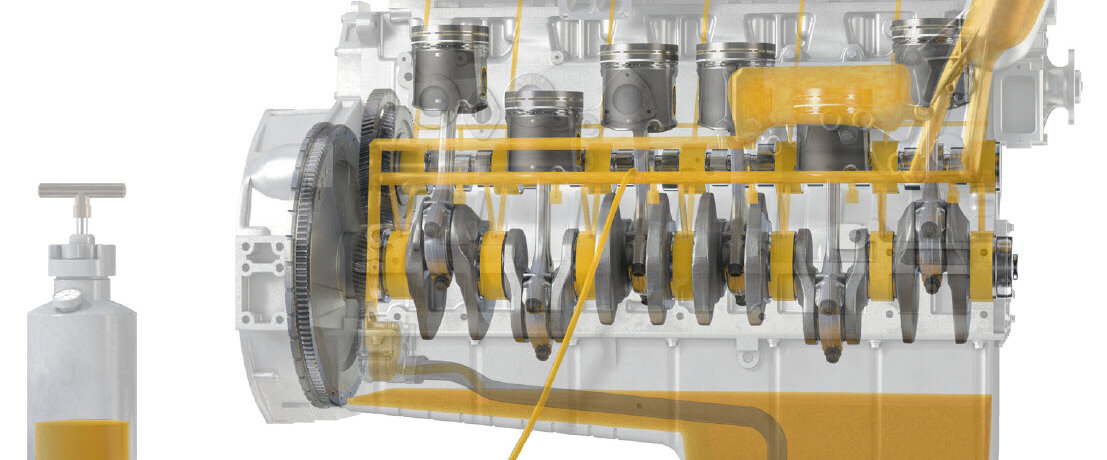

1. Using a pressure tank, the oil for the engine is pumped into the engine via a screw connection on the oil pressure system (Fig. 1 and 2). Suitable connection points are the oil channel sealing plugs specified by the engine manufacturer, or the connecting point of the oil pressure switch OPS.

2. Oil is now pumped into the engine until oil escapes from the oil lubricating points furthest away from the oil pump. These points are usually the rocker arm bearings (Fig. 3) or the bearing positions of camshafts at the top. The maximum permitted oil pressure in engine operation must not be exceeded. During the pressure oil filling, the engine should be turned by hand in the direction of rotation.

3. Ensure that the oil level of the oil filler tank does not fall below the minimum level during filling. If air is sucked in during pressure oil filling and pumped into the oil circuit, the entire process must be repeated.