Fuel delivery modules: Notes for installation

Information on use

What do you need to pay attention to when installing a fuel delivery module? What are the markings on the flange cover for? What are the most common causes for a pump to fail? What are fluid-level sensors and how do they work? This video gives you the answers.

0:15 – 1:20 Observe the markings

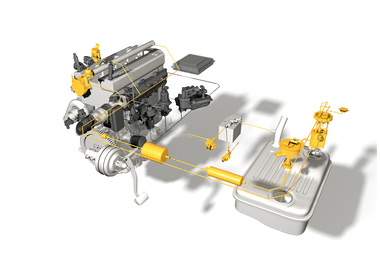

In order to comply with the legal requirements for tank leak-tightness, ever more components are now located directly in the fuel tank, in addition to the fuel delivery module.

Usually, there are markings on the fuel tank and flange cover to prevent installation errors and leakage. The fuel delivery module should always be inserted so that these markings are opposite each other.

1:20 – 1:55 Avoid dirt

Dirt in the fuel tank is the main cause of failure for fuel pumps. It can block up the pump system or clog up the preliminary filter, causing the pump to run dry.

Therefore, always take care not to allow any impurities to enter the fuel tank.

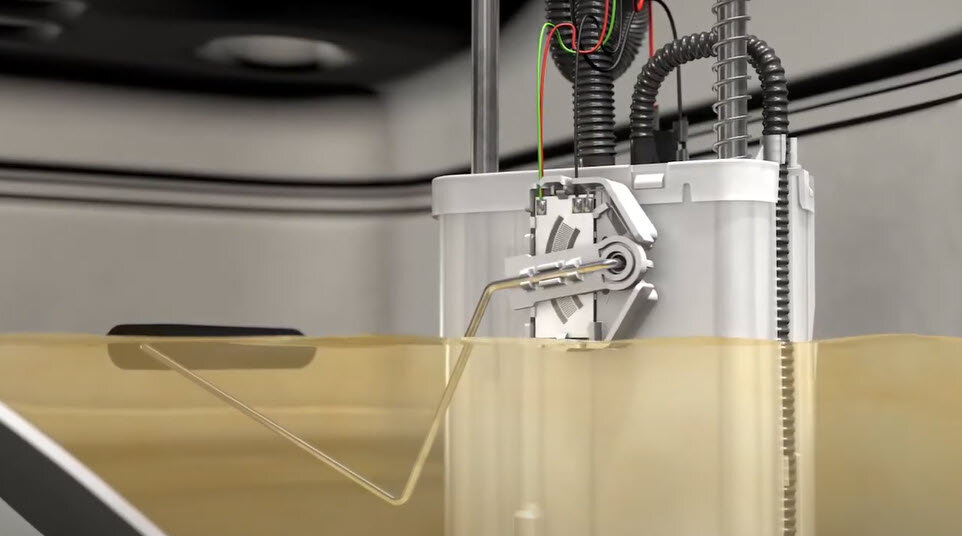

1:55 – 3:10 Damped sender unit

Fuel delivery modules generally have a fluid-level sensor that measures the fuel level using a lever arm. The lever arm can be moved easily. To ensure that the needle in the tank indicator does not vibrate due to the quick wave-like movements in the fuel level, the movement of the needle in the display instrument is damped.

Other manufacturers do not damp the needle, but rather the fluid-level sensor itself is fitted with a damping device that offsets the quick movements in the fuel level. These damped fluid-level sensors are difficult to move. They must never be moved forcefully, or they will bend or break.