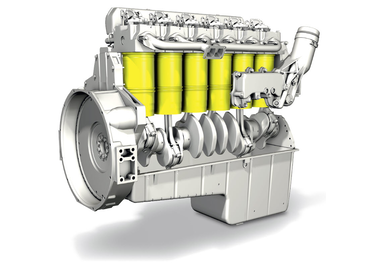

Fitting the pistons

Information on use

What do I need to watch out for when fitting pistons? When installing pistons, there are many things to watch out for — from ensuring the pistons and connecting rods are assembled flawlessly and making sure that the pistons are inserted into the cylinder correctly to performing a proper test run on the engine. Our step-by-step guide demonstrates how to perform some of these steps and provides valuable tips and advice on working with pistons.

Assembly of pistons and connecting rods

For swimming pins

Retainer rings are supplied for fixation of the pin. Used retainer rings must no longer be used. To prevent lasting deformations, the retainer rings must not be pressed together too hard.

Assembly of connecting rod with fixed pin

The bore in the connecting rod eye must have a pressfit to the pin. For assembly the connecting rod is to be heated to 280 - 320 °C (no open flame!). Afterwards quickly insert the well oiled and cold pin into the connecting rod eye. To ensure correct positioning of the pin in the connecting rod, a device with stop pin is to be used.

Whether the rings have safely locked into the grooves can be checked by slightly turning them. The joint of the retention must always be in direction of the piston stroke.

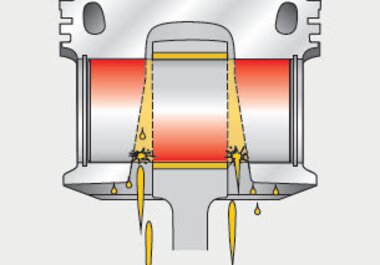

Checking the piston rings

Spiral expander oil control rings

The joint ends of the spiral expander should always be exactly opposite the ring joint for spiral expander rings. For spiral expanders with Teflon sheath, the sheath rests against the ring joint. In addition, for spiral expander rings with locating hook it is important that the locating hook is locked into the oil slot.

3-part steel rail oil control rings

During transport the spiral ends are untightened and can slip one above another. The position might need to be corrected before installation. Both colour markings at the spiral ends must be visible. If they are not visible, the spiral has overlapped and the ring is not working. The ring joints of the 3-part oil control ring (the two steel rails and the expander spring) must be turned against each other by 120° each before installation.