Damage to engine bearings: Overheating damage

Information on diagnostics

Is the engine bearing melted or burnt? Are there other signs of damage in the engine bearing shell in addition to initial rubbing marks, seizures and edge riding? You can find out how to detect heat cracks and melting areas and what to do here.

Introduction

Overheating damage is the result of dramatic temperature development in the engine bearing shell, which goes hand-inhand with acute mixed friction. This is why heat cracks, discolouration and fusing are also always displayed for initial rubbing marks or seizure.

The heat dissipation provided by the lubricant plays a central role here. If heat dissipation is no longer provided, this causes complete failure. Even with the initial signs of overheating, local changes to the microstructure occur and the integrity of the material is reduced. Heat cracks form at the affected areas.

Possible causes

- Consequential damage due to increasing temperature development as a result of initial rubbing marks, seizure or edge wear

- Insufficient heat dissipation provided by the lubricant

Remedy

If overheating damage occurs, the bearing must be replaced and the causes investigated. In the event of consequential damage, the cause of the primary damage must be rectified. If no further damage to the bearing is visible, the lubricant circuit and the stress on the bearing must be checked.

Heat cracks

Description

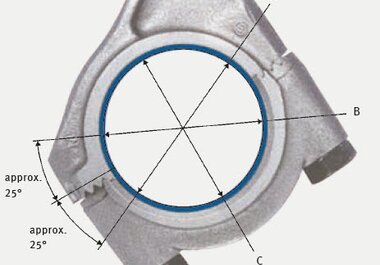

- A network of cracks is visible

- Fusing and discolouration of the bearing shell

Cap and rod-side conrod bearing shell Steel-bronze composite with galvanic coating

-> Clear discolouration and fusion is visible on the sliding layer of the seized bearing shells. The crack formation is above all recognisable in the area of the edge.

Fusing of the sliding layer

Description:

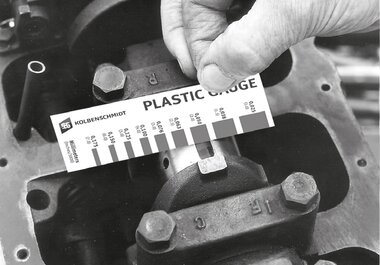

- Material displacement and smearing visible in the sliding surface

- Accompanied by heat cracks and discolouration of the bearing shell

Cap-side conrod bearing shell Steel-bronze composite with galvanic coating

-> White fusion deposits are visible in the galvanic layer.

Discolouration of the sliding layer and/or the back of the bearing

Description

- Blue-ish to black discolouration of the sliding layer or on the back of the bearing

- Accompanied by lumps and material removal/displacement

Rod-side conrod bearing shell Steel-bronze composite with galvanic coating

-> Following bearing seizure, the back of the bearing is black in colour.

Cap-side conrod bearing shell Steel-bronze composite with galvanic coating

-> The tarnishing colour can be seen in the sliding layer.