Damage due to engine running-in during idling

Information on use

What mistakes could be made when running in an engine? After installation, is it permitted to operate the engine at idling speed for hours? What damage could occur? In this article, find out how reconditioned engines should be run in.

SITUATION

In many repair shops or reconditioning companies, a damaging approach to engine running-in is used. Following installation, the engine is left idling for several hours or often even days. There is often a misconception that this running-in method is particularly gentle, as the engine is not stressed, which helps to prevent damage. The opposite is actually true: Hour-long engine operation at idling speed is extremely harmful for the engine. Engine running-in at idling speed is not possible. This method can lead to severe wear or damage.

PROBLEMS ASSOCIATED WITH RUNNINGIN AT IDLING SPEED

- The inadequate engine speed means that the oil pump generates too little pressure and does not supply enough oil to the lubricating points.

- The engine bearings are not properly lubricated and cooled. Dirt and running-in abrasion are not flushed out of the bearing positions.

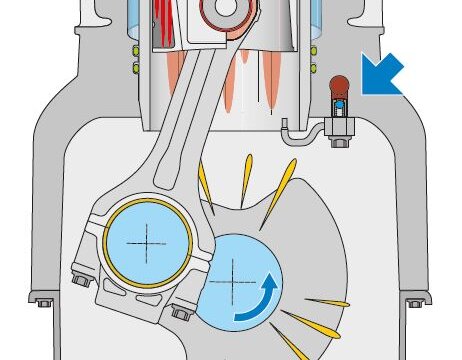

- Not enough oil emerges from the engine bearings. With the result that too little splash oil is sprayed onto the cylinder wall. Dirt and abrasion are not washed off, causing increased wear as early as the running-in phase (Fig. 1).

- The pressure valve (arrow in Fig. 1) for the piston spray cooling does not open at idling speed. The piston is not cooled and a lack of oil droplets leads to inadequate lubrication at the piston pin and the connecting rod bearing bush.

- Turbochargers are poorly lubricated and cooled. Idle mode for just 20 minutes is sufficient to be harmful to a turbocharger, not only when running-in, but also in the course of normal operation.

- Components such as valves, camshaft and rocker arm, which are located further away from the oil pump in the oil circuit, may be supplied with insufficient oil or even no oil at all.

- Piston rings cannot provide a perfect seal at idling speed. Hot combustion gases leak past, heat up the cylinder wall and damage the oil film. Under unfavourable conditions oil may even get into the combustion chamber. Result: The emergence of blue smoke and oil leakage from the exhaust.

LUBRICATION AT SPEED

Fig. 2 illustrates the engine lubrication situation at medium engine speed. Thanks to the higher engine speed, sufficient oil pressure is available to open the oil injection jet valves and thus supply the piston cooling oil ducts with fresh oil (01). The piston cooling oil dripping back additionally lubricates and cools the piston pins. The cylinder surfaces beneath the pistons are reliably lubricated with a sufficient quantity of centrifugal oil emerging as intended from the engine bearings of the crankshaft.

RUNNING-IN OF RECONDITIONED ENGINES

The engine must be run in on the road if no test rig is available for implementing a defined running-in program.

RECOMMENDATIONS FOR RUNNING-IN ON THE ROAD

- The vehicle should not be fully laden

- Run the engine at constantly changing speed levels not exceeding 2/3 of the maximum speed

- Avoid underrevving

- Avoid maximum gear speeds

- Avoid lengthy uphill driving (excessive load)

- Avoid lengthy downhill driving (insufficient load and undesirable overrun condition)

- Do not use the engine brake system

- Do not travel at top speed

- Do not travel at extremely hot ambient temperatures

- No long downtimes at idling speed (e.g. stopping at traffic lights, traffic jams)

FURTHER ADVICE

- Keep a constant check on the oil level during the running-in phase. The oil consumption may be higher during the running-in phase. It is advisable to check the oil level every 50 to 100 km and to top up the oil if necessary. In the event of a noticeable drop in the oil level on the oil dipstick, continue to check at shorter intervals.

- Do not overfill the engine with oil

- Important: When changing the oil after 1000 km, also replace the oil filter.