Damage due to abnormal combustion 2/3

Information on diagnostics

What is pre-ignition and how does it happen? Why has the piston crown melted behind the piston rings? What happens when the injection nozzles of direct injection diesel engines do not maintain their injection pressure? This article gives you the answers.

Removal of material by melting from the piston head and piston skirt (petrol engines)

- The piston head has melted through behind the piston rings.

- The piston skirt has not seized; melted material has been worn away off the damaged area onto the piston skirt.

Damage assessment

The removal of material by melting from piston heads in petrol engines is the result of glow ignition on pistons with mostlyflat crowns and relatively large quenching areas. Glow ignition is triggered by glowing parts in the combustion chamber that are hotter than the self-ignition temperature of the air-gas mixture. These are essentially the spark plug, the exhaust valves and any oil carbon deposits on the combustion chamber walls.

In the quenching area, the piston head is heated up significantly due to the glow ignition. The high temperatures cause the piston material to go soft. Material is carried away as far as the oil control ring due to the combined effects of inertia force and combustion gases entering the damage area.

Possible causes for the damage

- Heat value of the spark plugs too low.

- Mixture too lean, resulting in higher combustion temperatures.

- Damaged valves or insufficient valve clearance, causing the valves to not close correctly. The hot combustion gases streaming past cause the valves to start to glow. This primarily affects the exhaust valves, as the intake valves are cooled by the fresh gases.

- Glowing combustion residue on the piston crowns, the cylinder head, the valves and the spark plugs.

- Unsuitable fuel with an octane rating that is too low. The fuel quality must correspond to the compression ratio of the engine, i.e. the octane rating of the fuel must cover the octane requirements of the engine under all operating conditions.

- Petrol contaminated by diesel, which lowers the octane rating of the fuel.

- High engine or intake air temperature caused by inadequate ventilation of the engine compartment.

- General overheating of the engine.

Material removal/fusion due to melting on the piston head (diesel engines)

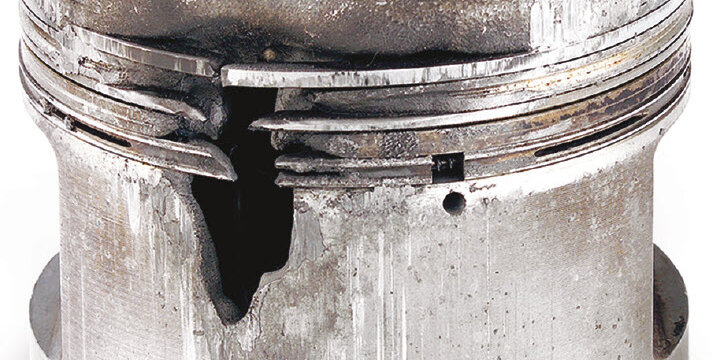

Fig. 1:

- Piston head completely destroyed.

- Piston top land melted as far as the ring carrier.

- Seizure marks and damage on the piston skirt due to melted, worn down piston material.

- Ring carrier partially detached.

- Damage (impact marks) in all combustion chambers due to piston material and detached ring carrier parts.

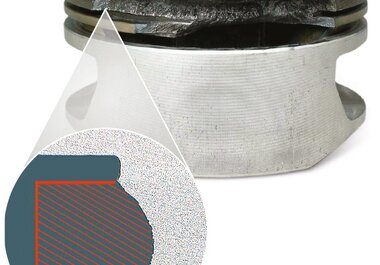

Fig. 2:

- Erosive-type removal of material due to melting on the piston crown or the piston top land in the injection direction of the nozzle jets.

- No seizure marks on the piston skirt or the piston ring zone.

Damage assessment

This type of damage occurs particularly on diesel direct injection engines. Prechamber engines are only affected if the prechamber is damaged and the fuel is therefore also injected directly into the combustion chamber.

If, in a diesel direct injection engine, the injection nozzle of the affected cylinder cannot maintain its injection pressure, oscillations in the injection line can cause the injector nozzle needle to lift again. Fuel is injected into the combustion chamber again. If the oxygen has been used up, the fuel droplets stream through the combustion chamber and end up on the piston crown. There they burn away with a great deal of heat and the piston material becomes soft.

The inertia force and the erosion due to the combustion gases speeding past tear out individual particles from the surface (Fig. 2) or carry away the entire piston head (Fig. 1).

Possible causes for the damage

- Leaking injection nozzles or stiff/jammed injector nozzle needles.

- Broken or worn nozzle springs.

- Faulty pressure relief valves in the fuel injection pump.

- Injection quantity and injection timing not set in accordance with the engine manufacturer‘s specifications.

- On prechamber engines: Prechamber defect in conjunction with one of the above possible causes.

- Ignition delay due to insufficient compression caused by excessive gap dimensions, incorrect valve timing or leaking valves.

- Excessive ignition delay caused by diesel that is reluctant to ignite (cetane rating too low).

- Poor charging due to defective turbocharger.