Troubleshooting in exhaust gas recirculation system on Otto and diesel engines

Basic information

Back to search

Information on the product

What is exhaust gas recirculation? Why is exhaust gas recirculated and how does this affect pollutant emissions? Which components are fitted in the EGR system? Find the answers here.

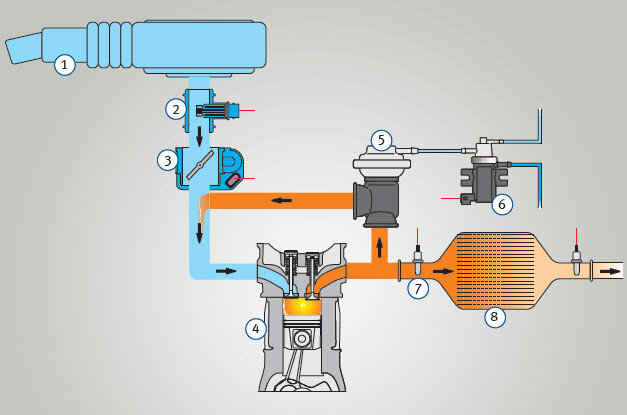

Vehicle: all vehicles equipped with exhaust gas recirculation system Products: Pos. 2, 3, 5, 6, 7 (see figure)

Exhaust gas recirculation (EGR) is a reliable and practice-proven method of emission control: As a result of exhaust gas, the oxygen content in the air-fuel mixture is reduced, and consequently the combustion temperature in the cylinders lowered. Since harmful nitrogen oxides (NOx) are mainly produced at high temperatures and pressures, it is possible to reduce the NOx concentrates emitted to the environment by up to 50%. On diesel engines, the formation of soot particulates is lowered by approx. 10%.

Exhaust gas recirculation is only activated at defined operating points. On petrol engines this is normally the case above idling and up to upper part load, on diesel engines up to approx. 3000 rpm and medium load.

Exhaust gas recirculation is only activated at defined operating points. On petrol engines this is normally the case above idling and up to upper part load, on diesel engines up to approx. 3000 rpm and medium load.

- Air filter

- Air mass sensor

- Throttle valve/control flap

- Cylinder

- EGR valve (in this case:pneumatic)

- Electropneumatic pressure transducer

- Lambda probe (Otto)

- Catalytic converter

| EGR at a glance | Diesel engine (all injection types) |

Petrol engine (manifold injection) |

Petrol engine (direct injection) |

|---|---|---|---|

| Effects | Nitrogen oxides -50% Particulates -10% Less hydrocarbons emitted Less noise emitted |

Nitrogen oxides -40% Fuel consumption -3% Less CO2 |

Nitrogen oxides -50…60% Fuel consumption -2% Less CO2 |

| Return rates | Max. 65% | Max. 25% | Max. 50% (with stratifi ed charge) Max. 30% (with homogenous operation) |

| Others | EGR cooling is required for vehicles with higher weight class |

EGR cooling under discussion | High EGR rates at high load |

Components of exhaust gas recirculation system (EGR)

The EGR valve meters the amount of recirculated exhaust gas.

It is added either at the exhaust manifold or at the intake air system, or it is located in a heatresistant exhaust-gas pipe which connects the exhaust manifold to the intake air system. Pneumatic EGR valves are actuated by way of vacuum via electromagnetic valves:

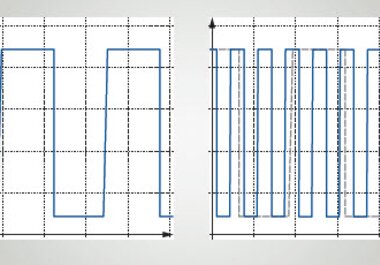

On basic systems with an electric switchover valve, the EGR valve only has an open-close function.

On systems provided with an electro-pneumatic pressure transducer (EPW), the EGR valve is infinitely adjustable.

The vacuum is taken from the intake manifold or generated by a vacuum pump. Electric or electromotive EGR valves are actuated direct by the control unit and no longer need any vacuum or solenoid valve.

It is added either at the exhaust manifold or at the intake air system, or it is located in a heatresistant exhaust-gas pipe which connects the exhaust manifold to the intake air system. Pneumatic EGR valves are actuated by way of vacuum via electromagnetic valves:

On basic systems with an electric switchover valve, the EGR valve only has an open-close function.

On systems provided with an electro-pneumatic pressure transducer (EPW), the EGR valve is infinitely adjustable.

The vacuum is taken from the intake manifold or generated by a vacuum pump. Electric or electromotive EGR valves are actuated direct by the control unit and no longer need any vacuum or solenoid valve.

EGR valves on diesel vehicles have large opening cross-sections because of their high return rates.

01: Pneumatic EGR valve

02: Pneumatic EGR valve with position detection

03: Electric EGR double-seat valve

On EGR valves in petrol engines, the cross-sections are considerably smaller.

04: Electric EGR valve with connection to the coolant circuit

05: Pneumatic EGR valve

06: Electric EGR valve