Sealing problems and piston ring damage

Fuel flooding

Information on diagnostics

Fuel flooding often results in damage to the piston rings. Why are the reasons for worn piston rings often interpreted incorrectly? You can read in this article how fuel flooding is caused.

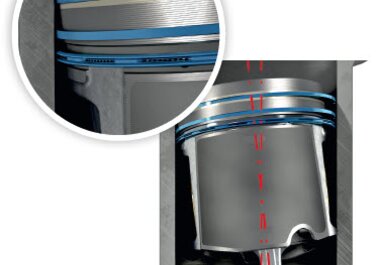

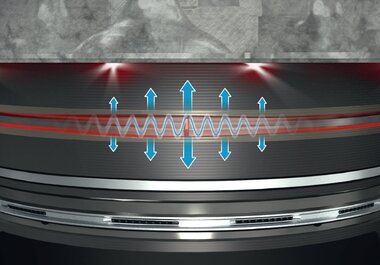

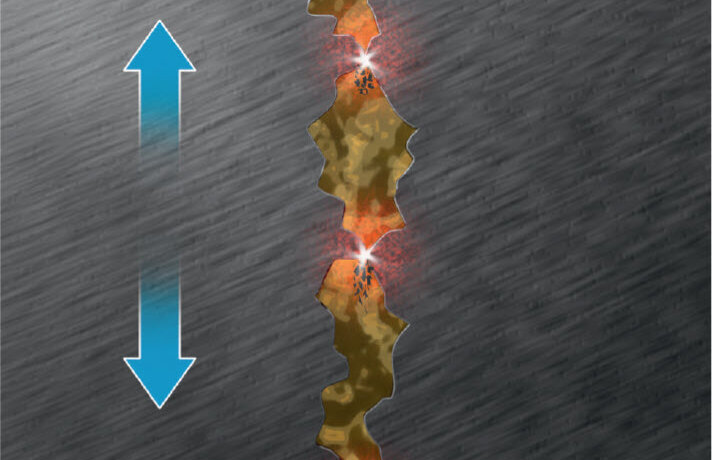

After damage due to dirt, damage and wear caused by fuel flooding is the second most common cause of damage on piston rings. In the event of fuel flooding, the oil film on the cylinder wall suffers so significantly that the piston rings rub metal on metal against the cylinder wall and quickly lose radial wall thickness. Metal contact between the piston rings and the cylinder wall (Fig. 1) may only occur briefly and in exceptional cases (e.g. during a cold start) and is not permitted in normal engine operation. The service life of pistons, piston rings and cylinder bores suffers significantly and is drastically shortened. In normal state, the interacting sliding parts are always separated from metal contact by an oil film (Fig. 2). Here, the oil film must therefore be thicker than the unevenesses on the surfaces of the interacting sliding parts.

During engine operation, combustion faults often result in an accumulation and condensation of fuel on the cylinder wall. In this case, the oil film is thinned or washed off. The resulting mixed friction causes the piston rings to wear completely within a few thousand kilometres. The performance drops and oil consumption rises.

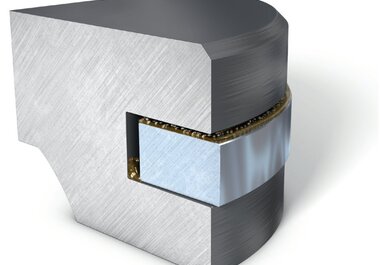

Mixed friction leads to significant radial wear on the piston rings and the cylinder surface. This is clearly visible on the two scraping lands of the oil control ring. Fig. 3 shows a new oil control ring and an oil control ring worn through mixed friction. The two scraping lands are completely worn down. The engine the ring comes from suffered from excessive oil consumption. Radial wear such as this, that not only occurs on the oil control rings, can almost always be traced back to fuel flooding.

Particularly if the extent of the wear is not equal on all pistons, mixed friction wear due to fuel flooding is the only possible explanation. This situation is actually extremely common and is proof that the rings are not worn due to suspected poor material quality or faulty cylinder machining. If this were the case, the wear would occur evenly on all pistons and piston rings and not just on specific cylinders.

Mixed friction wear caused by fuel flooding occurs on petrol and diesel engines equally.

With petrol engines, frequent short-distance drives (particularly with carburettor engines) and misfiring are the main causes. Petrol engines require a much higher fuel quantity to start up and in the warm-up phase than at operating temperature. In the case of frequent short-distance drives, the condensed and stuck on fuel on the cylinder wall may not be able to vaporise and binds with the engine oil. This leads to oil dilution and mixed friction due to the loss of viscosity in the engine oil. With petrol engines, incorrect spark plugs or ignition coils can also cause fuel flooding, as the fuel does not ignite and is therefore not burnt.

In diesel engines the injected fuel ignites when exposed to highly compressed air in the combustion chamber. Lack of compression (poor filling) or poor fuel quality result in ignition delays, incomplete combustion and liquid fuel collecting in the combustion chamber.

Further reasons for fuel flooding on diesel engines include

- Faulty and leaking injection nozzles

- Fault in the fuel injection pump or settings incorrect

- Incorrectly routed and poorly secured injection lines (vibrations)

- Mechanical faults (piston impact on the cylinder head) due to an incorrect piston protrusion dimension caused by reworking on sealing surfaces and the use of cylinder head seals with incorrect thicknesses

- Poor filling due to blocked air filters

- Poor filling due to faulty or worn turbocharger

- Poor filling due to worn or fractured piston rings

- Poor fuel quality (poor selfignition and incomplete combustion)

|

ATTENTION With this type of damage too, we must differentiate between whether the wear is only present on specific cylinders or on all cylinders. If damage is present on all cylinders, it is most likely a global cause, such as poor fuel quality or poor filling. If only individual cylinders are affected, faulty injection nozzles, spark plugs or high-voltage cables are the likely potential causes. |