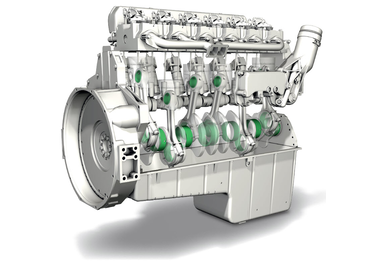

How to correctly install engine bearings

Information on use

What is the correct way to install engine bearings? What do you need to look out for if the bearing caps are cracked? What are sputter bearings? What do you need to look out for on the oil bores? How can you check that everything has been installed correctly? You can find out here.

Preparatory work 0:20 - 1:33

Attention: Take great care to keep everything scrupulously clean when working in the engine.

Take particular care with cracked bearing caps, as any soiling or damage at the points of fracture will mean that the bearing cap no longer fits exactly on the bearing block.

The next step is to perform a visual inspection and clean the parts. It is essential to use suitable solvents and cleaning products for this.

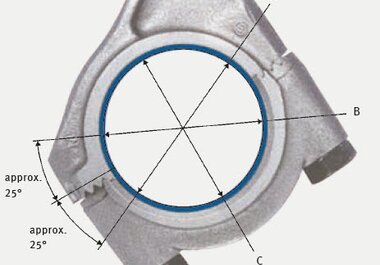

On used engine blocks, the bores must be checked before installing the new bearing shells.

Installation 1:33 – 4:30

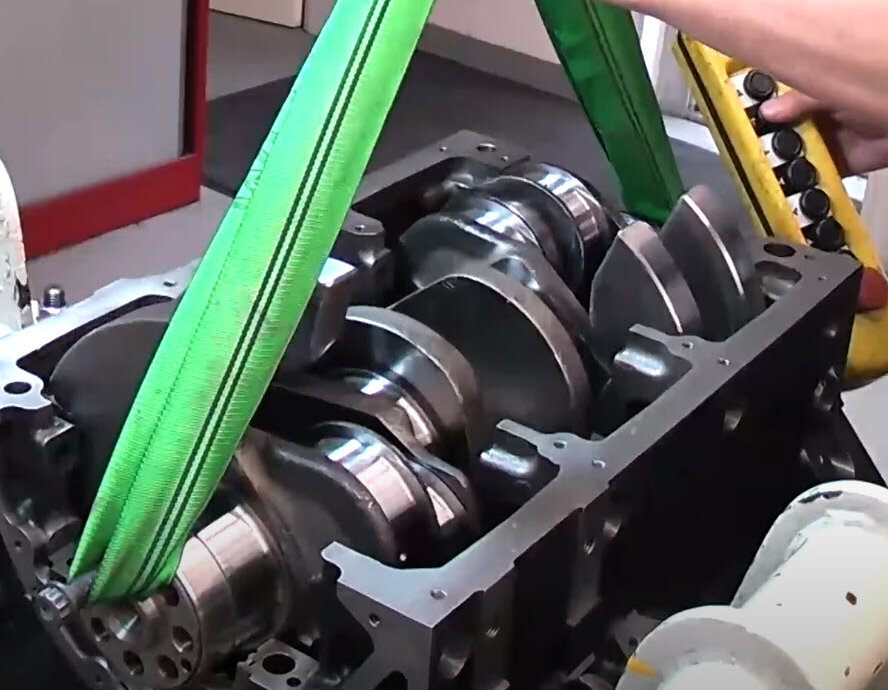

Before starting the installation work, clean the bearing centre line and the journals of the crankshaft again using a microfibre cloth.

To make sure you have the correct components, compare the old bearing shells with the new ones. Are the oil bores in the same position and do the oil grooves have the same design?

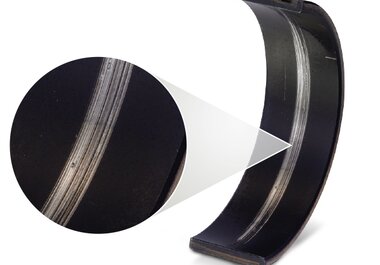

Ensure a precise fit when inserting the bearings. When assigning the bearing shells in the main bearing centre line, the position of the flanged bearing and the thrust washers is particularly important. Also observe the design of the individual bearing shells and the position of the oil bores. Sputter bearings are often used at the points that are subjected to higher loads.

The oil bores must be clean and clear when the bearings are inserted. The next step is to oil the sliding surfaces and carefully insert the crankshaft. Then position and tighten the bearing caps.

Inspection 4:18 – 4:47

Once the installation work is complete, check whether the crankshaft can turn freely and measure whether the axial clearance is within the defined tolerances.