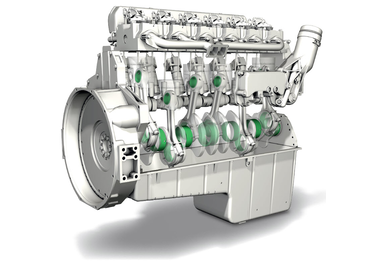

Engine bearings with polymer coating

Back to search

Information on the product

New systems require new technologies – the introduction of start-stop systems has placed new demands on engine bearings. The use of a polymer coating, for example, can reduce friction and increase wear resistance. Learn more about the advantages of engine bearings with low-friction plastic coatings.

European car manufacturers want to reduce the average CO2 emissions of their cars by 95 g/km by 2020. In the field of engine technology, some of the options being explored include start-stop technology and sailing mode. The new generation of engine bearings from KOLBENSCHMIDT contributes to cutting CO2 emissions to their target level. Motorservice now stocks these bearing sets as spare parts.

Characteristics

Until now, aluminium alloys were normally only used as a bearing metal in twomaterial bearings, with the steel back simply functioning as the reliable fit element in the housing. The aluminium alloy serves as the bearing metal, making it the interacting sliding partner of the shaft, which has to perform all of the engine bearing's other tasks. The new engine bearings possess an additional polymer sliding layer, permitting the bearing metal and polymer layer to take on different tasks, as they are adaptable, resistant to wear and strong at the same time – qualities that are, in fact, diametrically opposed. A specially developed aluminium alloy containing silicon was used as the bearing metal: it is both extremely tough and at the same time wear-resistant. Using a complicated application process, a polymer coating is applied to this aluminium alloy. The coating consists of a temperature- and dirt-resistant polyamide resin that contains a high level of frictionand wear-reducing bulking agents. By combining metal and polymer components, the new product is 20% stronger than conventional two-material bearings while also ensuring greater wear-resistance and less friction.

1 Steel back

2 AlSnSi bearing metal

3 Polymer sliding layer

2 AlSnSi bearing metal

3 Polymer sliding layer