Damage due to abnormal combustion 3/3

Information on diagnostics

What is glow ignition and how does it happen? What happens if you install an incorrect piston? What role does the bowl diameter play here? What is knocking combustion? How does it come about and what consequences does it have? This article provides the answers.

Hole in the piston crown (petrol engines)

- Piston crown has a hole that penetrates all the way through, covered by the molten material.

- Skirt area displays seizure marks. Reason: the high temperatures and the piston material that has been ground down.

Damage assessment

This type of damage is caused by glow ignition. Glowing components exceed the self-ignition temperature of the air-gas mixture in the combustion chamber. These are essentially the spark plug, the exhaust valve and any combustion residue present in the combustion chamber. As a result, the mixture ignites before it is due to be ignited by the spark plug. This means that the flame acts for longer on the piston crown than in the normal combustion process.

Within a short space of time the piston crown heats up so much as a result of glow ignition that the material there becomes soft. The softened material is then carried away as a result of the inertia force on the reciprocal movements of the piston and the fast-streaming combustion gases. As such the combustion pressure forces a hole in through the remaining thickness of the piston crown wall. In many cases there will not be any seizure marks.

|

NOTE Such rapid heating of a localised area on the piston crown is only possible as a result of glow ignition. |

Possible causes for the damage

- Heat value of the spark plugs too low.

- Mixture too lean, resulting in higher combustion temperatures.

- Damaged or leaking valves, or insufficient valve clearance, causing the valves to not close correctly. The combustion gases streaming past significantly increase the temperature of the valves, and the valves start to glow. This primarily affects the exhaust valves, as the intake valves are cooled by the fresh gases.

- Glowing combustion residue and oil carbon deposits in the combustion chamber.

- Incorrect injector installation dimension (missing or duplicate sealing rings).

- Unsuitable fuel with an octane rating that is too low. The fuel quality must correspond to the compression ratio of the engine, i.e. the octane rating of the fuel must cover the octane requirements of the engine under all operating conditions.

- Petrol contaminated by diesel, which lowers the octane rating of the fuel.

- High engine or intake air temperature caused by inadequate ventilation of the engine compartment.

- General overheating of the engine.

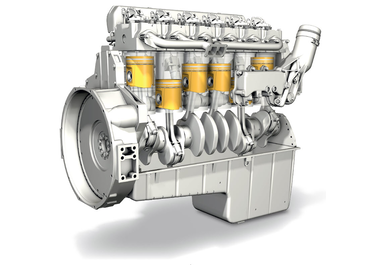

Piston head seizure due to the use of incorrect pistons (diesel engines)

- Localised score marks can be seen on the piston head, going all around the circumference of the piston.

- Score marks start at the piston crown and end at the second compression ring.

- Score marks are centred around the piston top land.

Damage assessment

This damage has been caused by abnormal combustion. However, the fault lies in the use of an incorrect piston, not with the fuel injection system. Engines are designed in accordance with the statutory prescribed emission standards. The pistons for the relevant emission standard are often barely any different to look at.

In this example, pistons with different bowl diameters were used on the same engine type to meet different emission standards. The piston for the Euro 1 emission standard (bowl diameter of 77 mm) was replaced during engine repair with a piston for the Euro 2 emission standard (bowl diameter of 75 mm).

Because of the smaller bowl diameter, the injection nozzle was also spraying onto the edge of the bowl rather than just into the bowl. The edge of the bowl and the piston material heated up at the points of contact and their thermal expansion therefore also increased. This led to the localised seizure marks. If the pistons used are not intended for the engine type and emission standard, this can result in serious abnormal combustion with unforeseeable consequences. Other less severe effects would be failure to comply with exhaust gas values, lack of engine performance and increased fuel consumption.

Possible causes for the damage

- Pistons with an incorrectly shaped bowl or an incorrect bowl depth or diameter.

- Deviating piston dimensions (e.g. compression height).

- Incorrect piston design. For example, a piston without an oil cooling gallery must not be used if the engine manufacturer specifies an oil cooling gallery for the particular application.

- Use of incorrect components or components that are unsuitable for the intended purpose (injection nozzles, fuel injection pumps, cylinder head gaskets or other components that affect the mixture formation or combustion process).

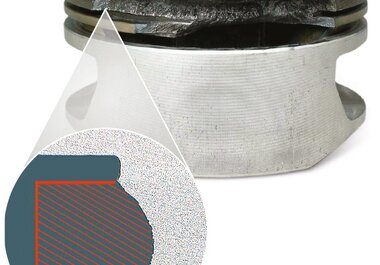

Erosion on the piston top land and on the piston crown (petrol engines)

Erosion-type removal of material from the piston top land (Fig. 2) or surface of the piston crown (Fig. 3).

Damage assessment

Erosion-type removal of material from the piston top land and from the piston crown always occurs as a result of extended periods of knocking combustion (medium severity). In the process, pressure waves spread in the cylinder and run down between the piston top land and the cylinder wall as far as the first compression ring. At the reversal point of the pressure wave, the kinetic energy tears out tiny particles from the surface of the piston.

Possible causes for the damage

- Fuel without suitable anti-knock properties. The fuel quality must correspond to the compression ratio of the engine, i.e. the octane rating of the fuel must cover the octane requirements of the engine under all operating conditions.

- Petrol has been contaminated with diesel. Cause: accidental refuelling with the wrong type of fuel or shared use of tanks or canisters for both types of fuel. Even very small amounts of diesel are already enough to significantly lower the octane rating of the petrol.

- Large quantities of oil in the combustion chamber, caused for example by worn piston rings, valve guides or the exhaust gas turbocharger, will reduce the anti-knock properties of the fuel.

- Excessively high compression ratio. Cause: combustion residue on the piston crowns and cylinder head or excessive machining of the block surface and cylinder head surface for engine reconditioning or tuning purposes.

- Ignition timing too advanced.

- Mixture too lean, resulting in higher combustion temperatures.

- Intake air temperatures too high. Causes: inadequate ventilation of the engine compartment or exhaust gas back pressure, failure to switch the intake air flap to summer operation in a timely manner or a faulty automatic switchover mechanism (particularly on older carburettor engines).

- Failure of the knock control system.

- Modifications to the control unit software.

|

NOTE

|