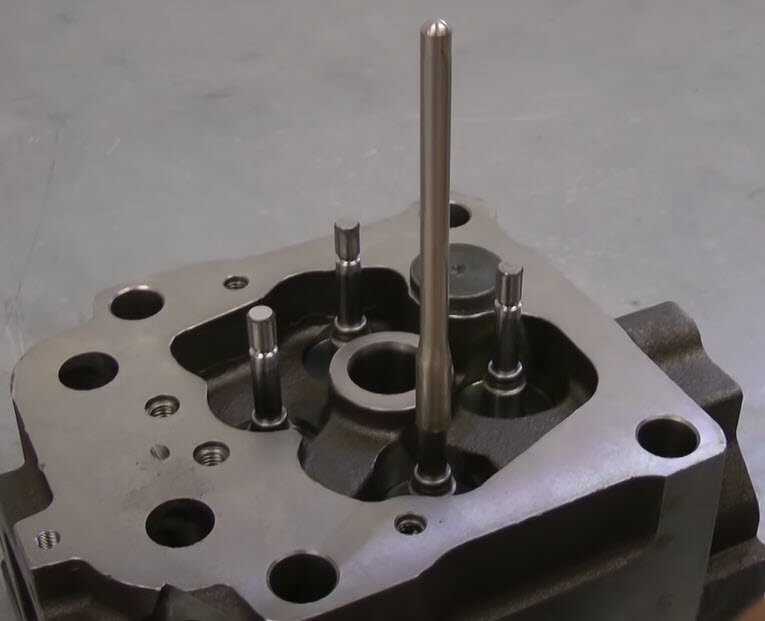

Completion of cylinder heads for utility vehicles

Information on use

How do you assemble cylinder heads? How do you test the valve tightness? How do you check the valve guide clearance? What are the reasons for loss of power and irregular running of the engine? What should you look out for when installing valves? This video answers all of these questions.

Preparation

Prior to mounting, the cylinder head and all applicable parts are cleaned and checked for wear and damage.

0:30 to 1:27 Checking the valves

The sealing area on the valve head must not be staved in. Minor wear can be resolved through reworking. The valve stem faces and the stem surfaces must not be damaged. Valves that have been damaged are to be rejected. The concentricity of the valves is checked with a dial gauge. Slight deviations in concentricity can be corrected with a valve grinding machine.

1:27 to 2:30 Checking the valve guide clearance

To determine the valve guide clearance, first determine the diameters of the valve guide and valve stem, then subtract the latter from the former. The clearance determined must be compared to the set-point values of the manufacturer.

After checking, the valves should be put back into the valve guide. It should then be checked whether or not they fit and close correctly. The valve stem seals must not be installed for this.

2:30 to 3:16 Measuring the valve recess/protrusion

The correct valve recess or protrusion is a prerequisite for smooth interaction of all components. Therefore, the dimension specifications of the engine manufacturer must be adhered to. If valves are positioned too deep in the cylinder head, this results in diminished compression. If a valve recess is too large, then it is likely that the wrong valve is in use. If they protrude too far into the combustion chamber, they can collide with the piston.

3:16 to 4:15 Valve tightness test

Valves that are not tight can lead to irregular engine running, loss of power or burning through of the valves.

The valve tightness can be tested with a low pressure testing device. Alternatively, the test can be carried out by spraying a small quantity of liquid onto the valves. When this happens, the liquid must not flow through the valves and valve seat inserts too quickly. If it does, then the valves are not tight.

4: 15 to 5:50 Inserting the valves

Oil the valves and push them into the guides. Next, mount the valve stem seals. A protective bushing can be used to prevent damage from occurring during this process.

The valve-springs must be checked for rectangularity and length, then mounted. Following mounting of the valve-springs and insertion of the valve cotter halves, the cylinder head is ready for assembly.