Adaptation to engine management

Various Pierburg components must be “learnt”

Back to search

Information on diagnostics

High idling after installation? New part on the engine control unit is not working or the new component is already faulty? What does "basic settings" mean on the tester?

We will tell you what you should bear in mind when installing a new component.

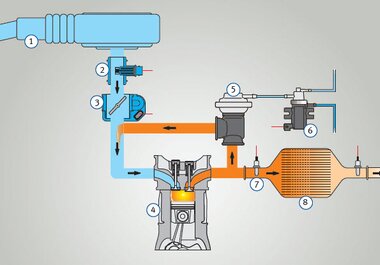

Modern vehicles are partly equipped with highly complex electronic components for which in the engine management controller highly specific characteristics data must be saved.

When replacing such a component against a new one, the engine management controller must first be made to “learn” the corresponding characteristics. If this is not done, then the result are typical customer complaints like “new component doesn’t work” or, for example, “higher idle speed after installation”.

Affected by this are among other things:

When replacing such a component against a new one, the engine management controller must first be made to “learn” the corresponding characteristics. If this is not done, then the result are typical customer complaints like “new component doesn’t work” or, for example, “higher idle speed after installation”.

Affected by this are among other things:

- air mass sensors,

- stepper motors,

- throttle bodies,

- idle speed devices and

- electric EGR valves.

When installing a new component, as a rule, observe the following:

- will according to the manufacturer’s information be an adaptation required?

- does the engine tester provide in its programme for the specific component (“default setting” or “adaptation”)?

- is there a special Pierburg Service Information document which covers the specific component?