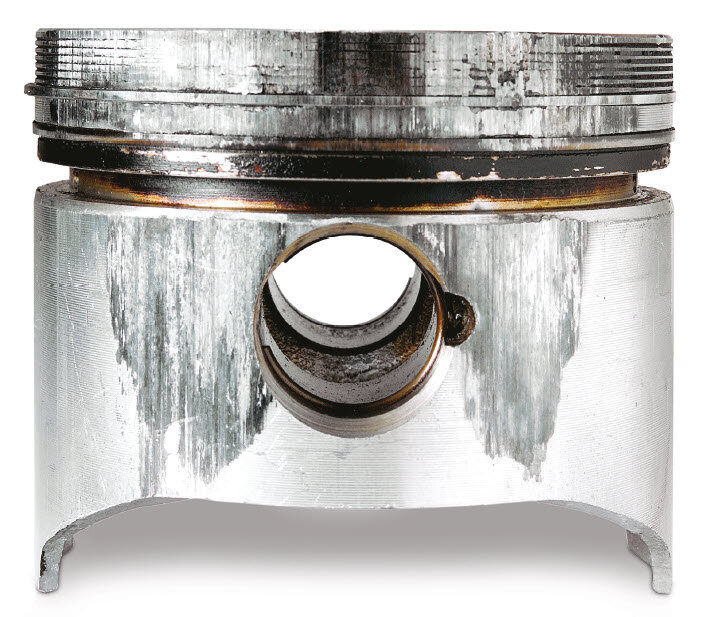

45° seizure marks

DESCRIPTION OF THE DAMAGE

- Seizure marks on both the pressure and anti-thrust sides, offset at approximately 45° to the piston pin axis.

- The seizures areas change from bright wear marks to relatively smooth, darkly discoloured areas of wear caused by rubbing (Fig. 1).

- Piston pin displays blue tempering colour (Fig. 3). Reason: piston pin bed has become hot due to insufficient clearance or a lack of oil.

DAMAGE ASSESSMENT

The piston pin boss has heated up excessively. The thin-walled and elastic piston skirt is able to compensate for the increased thermal expansion on the pressure and anti-thrust sides. The piston pin boss is stiffer and its expansion increases. The clearances are restricted and a piston seizure occurs. The piston seizure is centred around the transition between the piston pin boss and the piston skirt.

POSSIBLE CAUSES FOR THE DAMAGE

- Mechanical overload of the connecting rod bearing, e.g. due to abnormal combustion.

- Malfunction/fracture in the oil injection jet.

- Insufficient or no oil pump pressure.

- Insufficient lubrication when the engine was first taken into operation. The piston pin was not or was insufficiently lubricated when it was assembled.

- Failure of the connecting rod bush (piston pin seizure) due to insufficient clearance or lubrication.

- Installation fault during the process of shrinking the piston pin (shrink-fit connecting rod).

During the shrinking process, care must be taken to ensure that, immediately after the piston pin has been inserted, the piston pin bed is not checked for freedom of movement by tilting the piston back and forth. The temperatures are equalized between the two components immediately after the cool piston pin is inserted into the hot connecting rod. The heat introduction increases the thermal expansion of the piston pin as is the case during engine operation. If the bed is moved in this state, it can cause initial rubbing marks or seizure marks. This may cause stiffness or failure of the piston pin bed during engine operation. For this reason, allow the assembled components to cool down before checking the freedom of movement.

Side info