Wear on pistons, piston rings and cylinder running surfaces caused by the ingress of dirt

DESCRIPTION OF THE DAMAGE

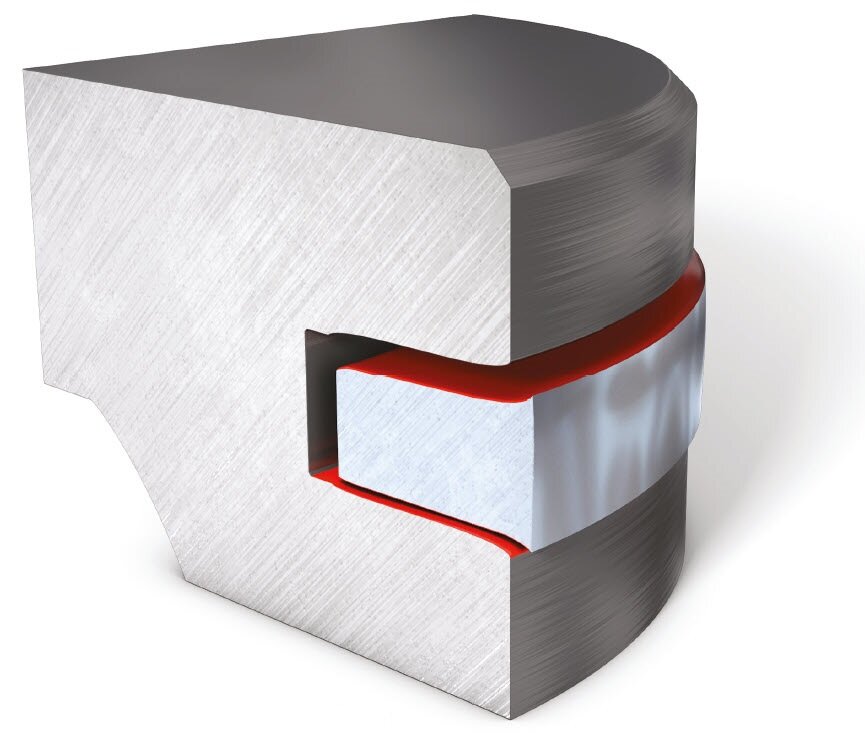

- Piston: matt, ground wear pattern on the skirt with fine, small longitudinal scratches on the piston top land and the piston skirt.

- Tool marks created during machining worn away.

- Worn compression ring edges, on the first piston ring in particular as well as ring groove edges (Fig. 2).

- Axial clearance of the compression rings substantially increased, in particular on the first piston ring.

DAMAGE ASSESSMENT

Abrasive foreign bodies in the oil circuit cause scratches on the piston and piston rings, a matt wear pattern on the piston skirt and roll marks on the ring flanks (Fig. 4 and 5). As the piston rings are worn on the running surfaces and edges, they can no longer seal the cylinder against oil passing into the combustion chamber. At the same time, the pressure in the crankcase increases as a result of combustion gases streaming past the cylinder. This may cause oil to escape at radial oil seals, valve stem seals and other sealing points. Roll marks on the piston rings are caused by dirt particles that become lodged in the ring groove. As the piston ring rotates in the groove it keeps running over the dirt particles, which creates the characteristic roll marks.

POSSIBLE CAUSES FOR THE DAMAGE

- Abrasive dirt particles that enter the engine with the intake air due to inadequate filtration, including:

- Missing, defective, deformed or poorly maintained air filters.

- Leaking points in the intake system, such as distorted flanges, missing gaskets or defective or porous hoses.

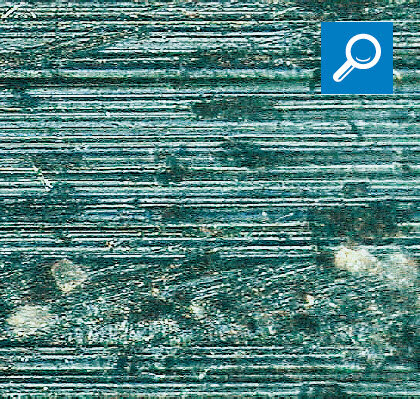

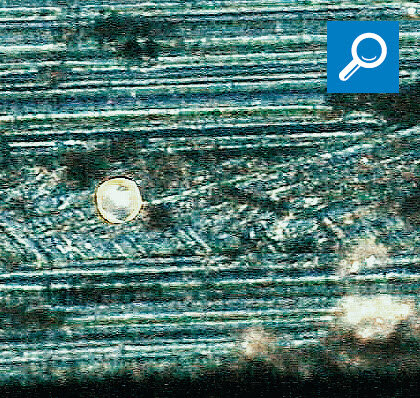

- Residual particles of dirt from engine reconditioning. Parts of the engine are often blasted with sand or glass beads during reconditioning work in order to remove persistent deposits or combustion residue from the surfaces. If the blasting material becomes deposited in the material and is not cleaned out properly, it may work its way loose when the engine is running, thus causing abrasive wear. Fig. 6 and 7 show microscopic images of damage caused by dirt, under polarised light. Fragments of the glass blasting material and entire beads of the glass can clearly be seen.

- If the first oil change is performed too late, the abraded particles generated when the engine is run in are spread through the oil circuit to the other interacting sliding parts where they cause more damage. The sharp oil-scraping edges of the piston rings are particularly prone to damage.

Side info